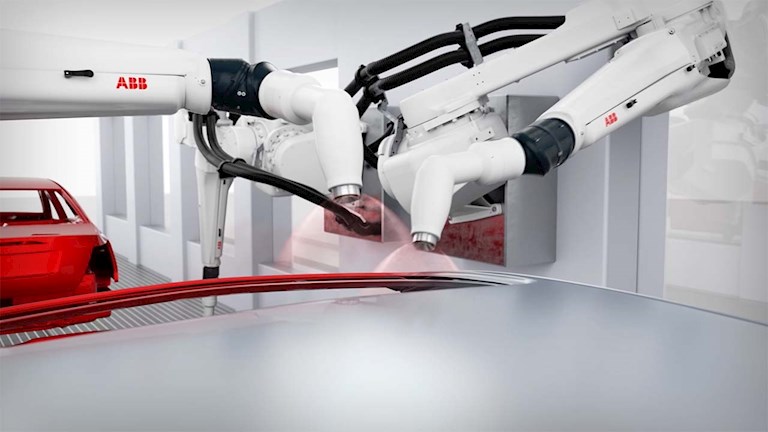

ABB's High-Efficiency RB1000i-S Paint Atomizers Drive Sustainability at Mazda Ujina Plant No. 1

Cutting-edge atomizers achieve 95-99% transfer efficiency, helping Mazda reduce emissions, energy use, and waste as the automaker accelerates toward carbon-neutral production by 2035.

Source of Image: Public Domain

- ABB's digitally-enabled RB1000i-S paint atomizers deployed at Mazda Ujina plant No. 1, Japan, to support ambitious sustainability targets

- Mazda estimates 60% of manufacturing CO2 emissions come from painting, highlighting its significance to carbon neutrality

- New RB1000i-S atomizers achieve up to 95-99% efficiency, reducing paint usage, waste, energy consumption and emissions

ABBs’ latest RB1000i-S high-transfer efficiency paint atomizers have been installed at Mazda’s Ujina plant, Japan as the automotive manufacturer accelerates efforts to achieve carbon neutrality in its global production facilities by 2035. The digitally-enabled atomizers, which began operation earlier this year, significantly reduce paint usage by increasing the paint transfer to the vehicle body through less overspray. Together with reductions in compressed air consumption and paint wastage during color changes, the new ABB atomizers are helping to reduce emissions in the paint process itself and in related paint booth equipment.

“Mazda states that 60% of CO2 emissions during their manufacturing process is due to painting, making it a key target for optimization as the company works to achieve carbon neutrality targets,” said Joerg Reger, Managing Director of ABB Robotics’ Automotive Business Line. “Our new RB1000i-S atomizers achieve up to 95-99% efficiency, while reducing paint usage and costs, volatile organic compounds (VOC) and energy consumption for waste fluid treatment in the paint booth, all supporting CO2 emission reduction.”

Mazda, which manufactures the CX-5 as well as the iconic MX-5 roadster as its Ujina plant No. 1 in Hiroshima, reported a 17% reduction in paint usage due to the improved transfer efficiency of the RB1000i-S, equivalent to a saving of approximately 30,000 liters of paint annually*. Energy consumption and maintenance frequency, such as replacing the protective masking that prevents overspray from affecting the equipment, have also decreased. The company achieved additional cost reductions during the integration by deploying the RB1000i-S atomizers on existing robots, supporting carbon neutral operations as well as the circular economy.

ABB’s RB1000i-S atomizers, which can be retrofitted to ABB and non-ABB robots, are an example of the company’s efforts to deliver smart and sustainable solutions to support the transition of the automotive industry. An upgrade kit that enables existing RB1000i atomizers to take advantage of the enhanced RB1000i-S specification by replacing key parts such as the bell cup and air shaping nozzle, is just one of a range of upgrades available that are designed to elevate existing installations to the latest technology, maximizing their performance and prolonging their lifetime while maintaining reliability and minimizing downtime. ABB has committed to covering at least 80% of its product portfolio with its Circularity Approach by 2030.