FANUC America Showcases Advanced Robotics and CNC Solutions at FABTECH 2025

From collaborative welding to flexible machining and smart painting, FANUC demonstrates scalable automation to boost productivity and efficiency for manufacturers.

Image Courtesy: Public Domain

FANUC America, the global leader in robotics, CNC systems, and factory automation, will showcase its latest innovations at FABTECH 2025, held September 8–11 at McCormick Place in Chicago. Designed to help manufacturers improve productivity, reduce labor challenges and increase flexibility, FANUC's solutions span robotic welding, industrial painting, CNC machining and collaborative automation.

At FANUC's Main Booth B17010 in the North Building, visitors will discover a versatile lineup of advanced robotic welding demonstrations designed specifically to help small to medium-sized manufacturers maximize efficiency and quality. These compact yet powerful work cells showcase the flexibility and versatility of FANUC's welding robot solutions.

Advanced Welding and Machining Solutions in Action

- Collaborative Precision – Live Collaborative Robot Welding: Two FANUC CRX-10iA cobots work in perfect harmony to assemble, weld and deburr a washer and nut component. One CRX-10iA uses a single axis positioner to hold the component while the other CRX-10iA welds the part together. Meanwhile, the CRX-30iA equipped with FANUC's 3DV/200 vision camera takes the welded and assembled part and performs both material handling and removal tasks. These IP67-rated cobots offer intuitive hand guidance, drag-and-drop programming and fast redeployment, making them ideal for high-mix, low-volume production environments.

- Coordinated Motion – Flexible Multi-Arm Welding: The new FANUC M-950/500F-28A material handling robot presents an excavator bucket to two Arc Mate/25-18D welding robots. Showcasing the flexibility of coordinated motion, the ARC Mate robots simulate welding the seams as the M-950 adjusts the bucket's angle for optimal weld access. This level of synchronization between handling and welding robots maximizes the production efficiency while maintaining perfectly coordinated motion.

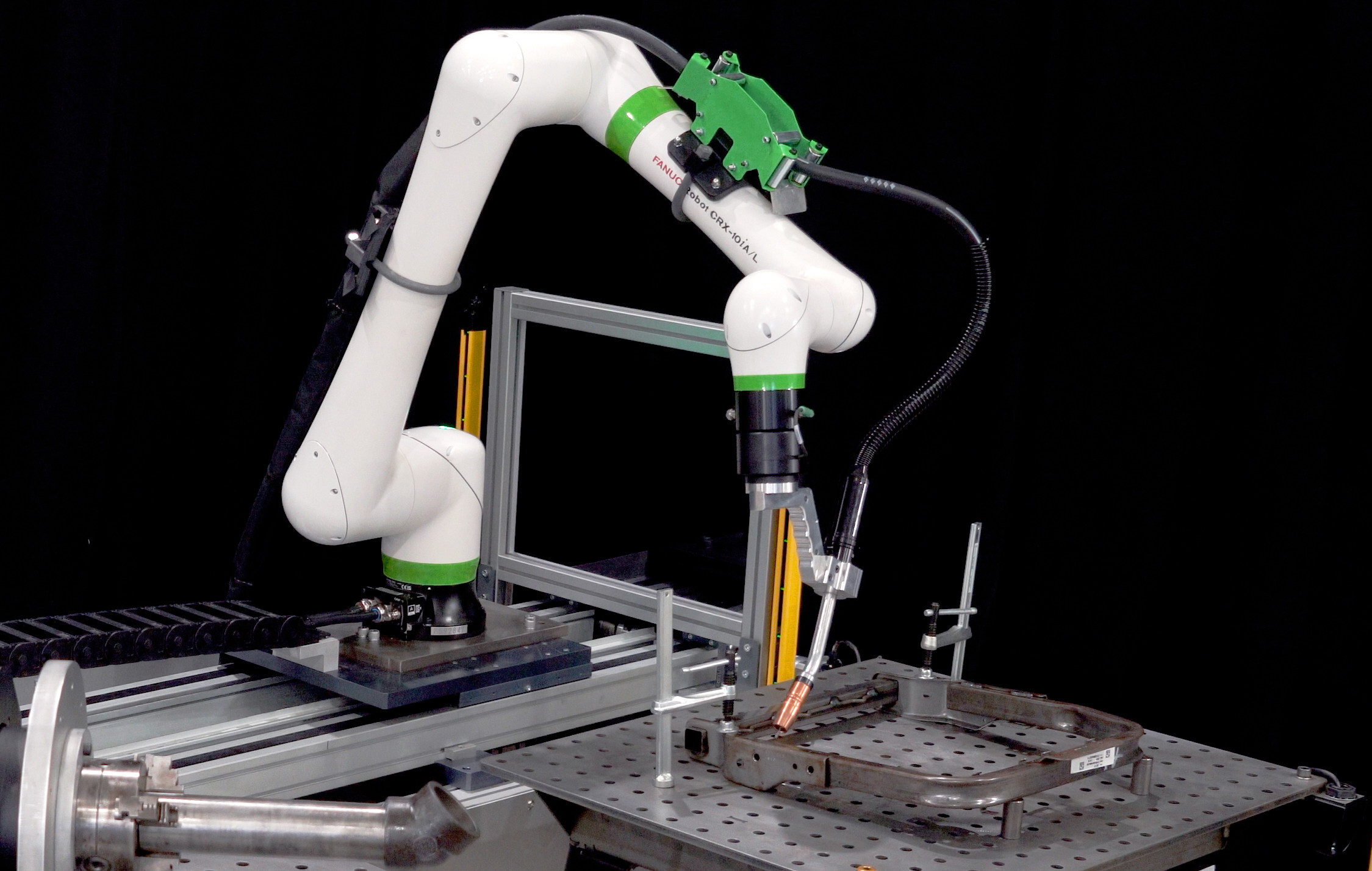

- Space-saving Efficiency – Multi-Station Arc Welding Cell: A CRX-10iA/L on a 7th axis rail services two operator stations. One station also includes a servo driven positioner along with the CRX-10iA/L to perform continuous arc welding while a human operator loads the next part in the other station—maximizing uptime and safety in compact workspaces. This efficient use of space and labor highlights FANUC's approach to scalable automation in constrained environments.

- Built for Tough Tasks – Flexible Robotic Wet Machining: FANUC's newly released M810/270F-27B robot demonstrates an emerging wet machining application by milling and drilling aluminum stock in real time. This demonstration highlights the robot's rigidity, accuracy and resistance to harsh environments—ideal for manufacturers seeking flexible, high-performance machining in demanding conditions.

CNC Solutions for Laser Applications

- FANUC will also present in the Main Booth its latest CNC automation technologies, including the new Alpha i-D Servo System and CNCs optimized for laser cutting machines

Smart Painting Robots for Complex Applications

At FANUC's Paint Booth D40121 in the East Building, FANUC will demonstrate how its industrial painting robots and paint cobots handle high-mix, low-volume production and hazardous environments:

- Intelligent Part Recognition – Visual Line Tracking with Cobots: A CRX-10iA/L Paint Cobot with FANUC 3DV iRVision will simulate painting electric guitar bodies, while a CRX-20iA/L Cobot also with FANUC 3DV iRVision loads and unloads parts using iRPickTool software—highlighting FANUC's precision in visual recognition and part handling.

- Multi-material Coating Control – Large-Scale Paint Automation: FANUC's paint robots support powder and liquid coatings, as well as fiberglass-reinforced plastic applications, offering scalable solutions for automotive, aerospace, and general manufacturing.

"As manufacturers of all sizes face increasing demands for flexibility and efficiency in their production process, FANUC continues to lead with automation solutions that are smart, scalable and easy to use," said Eric Potter, General Manager, Robot Application Engineering Segment, FANUC America Corp. "FABTECH 2025 is an ideal venue to demonstrate how our robotic and CNC technologies can help our customers solve real-world product challenges and drive long-term success."