OPEX and Peltier Partner to Deliver First Multi-Temperature Automated Cold Storage Solution

New AI-enabled, multi-deep cold storage capability integrates seamlessly with OPEX Perfect Pick® and Infinity® systems to transform refrigerated and frozen fulfillment

Image Courtesy: Public Domain

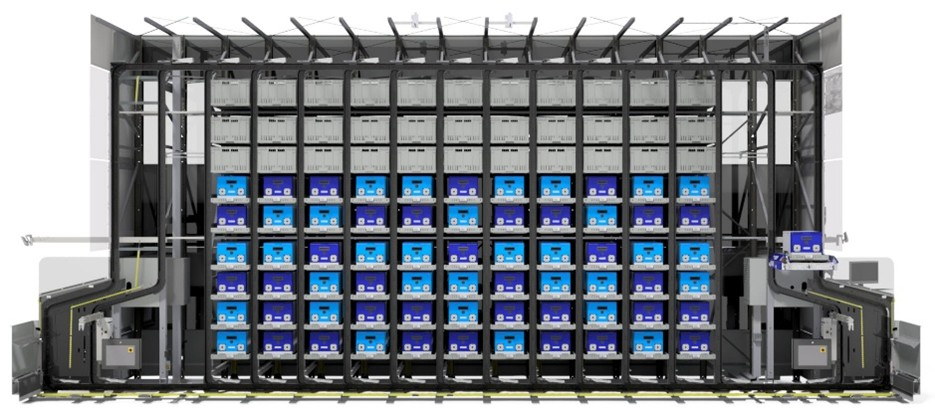

OPEX® Corporation, a global leader in Next Generation Automation providing innovative solutions for warehouse, document and mail automation, announced a strategic technology partnership with Peltier, an innovator in cold chain commerce, to offer a first-of-its-kind, multi-temperature zone, multi-deep cold storage solution for automated fulfillment systems. This collaboration introduces advanced multi-temperature capabilities to OPEX Corporation’s industry-leading Perfect Pick® and Infinity® automated storage and retrieval systems (ASRS), empowering customers in the grocery, pharmaceutical, and life sciences markets to seamlessly store and retrieve chilled and frozen products utilizing Peltier’s actively cooled, AI-enabled totes, eliminating the need for costly freezer chambers or specialized infrastructure.

“Many of our customers have expressed a need for multi-temperature capabilities, but are often dissuaded by traditional solutions that require costly infrastructure and complex system changes,” said Monty McVaugh, Head of Product, Warehouse Automation, OPEX. “By integrating Peltier’s tote technology into our existing framework, we can now deliver a flexible, scalable, efficient, and highly cost-effective solution without modifying our core systems.”

The Peltier ToteTM is designed with precise, individually controlled temperature setpoints and IoT connectivity, enabling real-time monitoring and management of storage conditions through integrated API messages. Power is provided to each tote while in multi-deep storage, and temperatures are maintained during transport by OPEX iBOT® robotic vehicles, ensuring continuous cold chain integrity. This groundbreaking innovation allows organizations to integrate refrigerated and frozen inventory directly into ambient warehouse environments, markedly simplifying operations and maximizing space utilization, while reducing capital expenditures.

Furthermore, this approach to cold storage enhances worker comfort and safety by eliminating the need for staff to operate in harsh freezer environments. The system’s physical AI capabilities drive dynamic energy management, and provide detailed reporting for sensitive products, including those subject to strict FDA regulations. Unlike conventional cold storage rooms, where refrigeration failure can result in total product loss, Peltier Totes isolate any potential issues to individual totes, minimizing both risk and waste. The totes are also environmentally friendly, powered by patented solid state cooling technology, as opposed to compressor based refrigeration systems that use harmful refrigerants.

“The Peltier Tote is fundamentally changing how the world applies cold storage in commerce,” said Hanson Li, Chief Executive Officer, Peltier. “Together, OPEX and Peltier are delivering an advanced solution that breaks the traditional paradigm, where cold and temperature were treated as major constraints. Customers can now optimize operations, processes, and space without these concerns. We’re very proud to be partnering with OPEX to offer a consequential solution to what has been a longstanding challenge for so many.”