GrayMatter Robotics Wins AFWERX SBIR Phase II Contract to Develop Autonomous Canopy Sanding System

AI-powered robotic solution aims to transform aircraft maintenance by improving precision, reducing labor time, and extending canopy service life.

Image Courtesy: Public Domain

Advanced Smart Robotic Canopy Sanding System Will Transform Maintenance Operations, Extend Service Life, and Enhance Mission Readiness for Aircraft

GrayMatter Robotics, a leader in AI-powered robotic surface finishing solutions, announced it has been awarded a Small Business Innovation Research (SBIR) Phase II contract by AFWERX, the innovation arm of the Department of the Air Force, to develop an autonomous robotic system for the precision sanding of canopies.

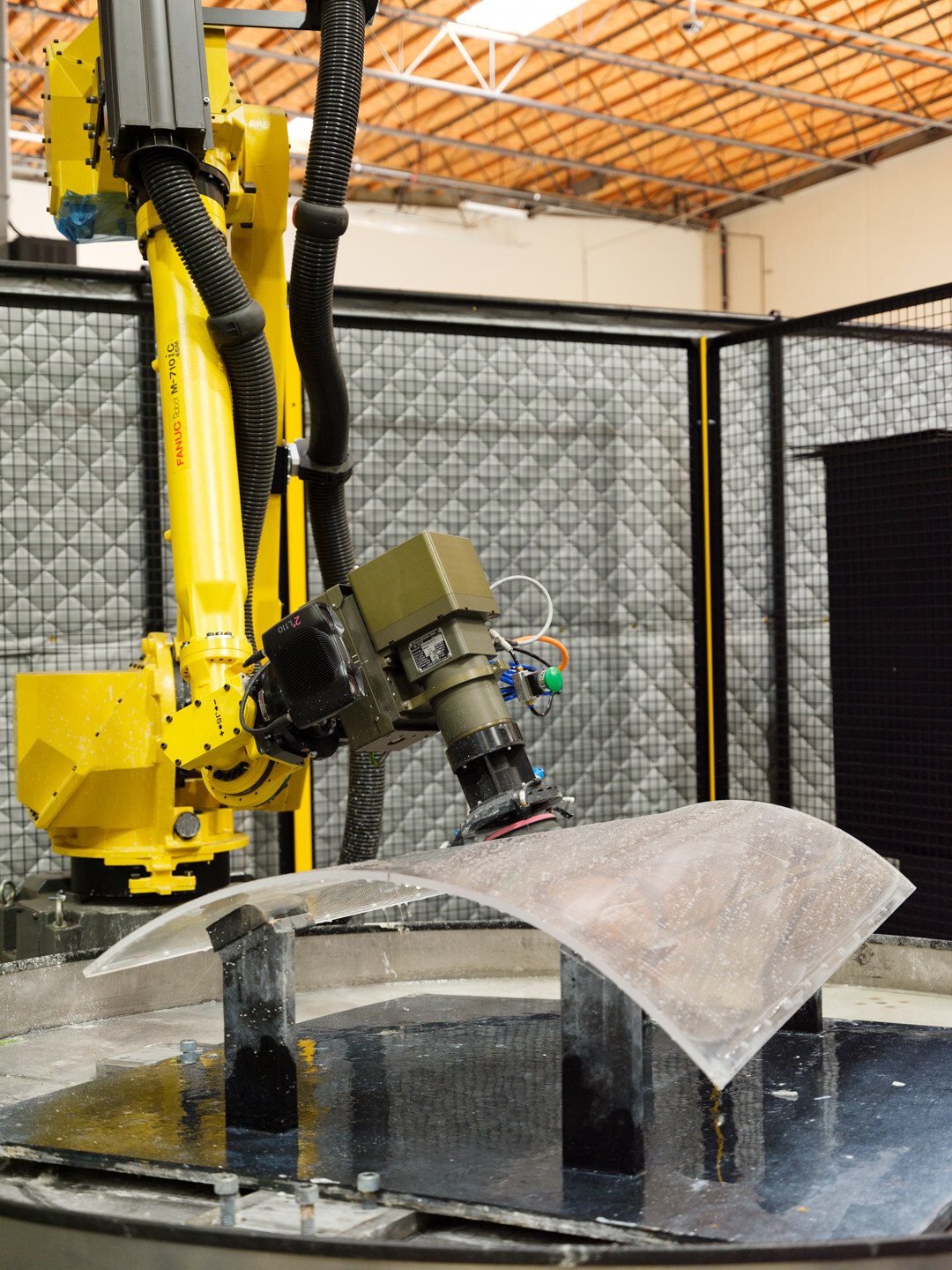

The Phase II contract builds upon GrayMatter's proven expertise in physics-informed AI and adaptive robotic systems, extending the company's breakthrough surface finishing technology to address one of aviation maintenance's most challenging and critical tasks. The Smart Robotic Canopy Sanding System will target maintenance and repair operations for acrylic and polycarbonate parts that accumulate scratches and surface damage on interior and exterior surfaces throughout their service life.

"Manual canopy repair is one of the most demanding precision tasks in aircraft maintenance, requiring exceptional skill and consuming valuable technician hours that could be deployed elsewhere," said Ariyan Kabir, CEO and co-founder of GrayMatter Robotics. "Our system will deliver the consistency and precision needed to restore optical clarity while dramatically reducing maintenance time and eliminating the variability that leads to rework."

The system leverages GrayMatter's proprietary GMR-AI™ platform, integrating advanced 3D sensing, force-adaptive control, and autonomous trajectory generation and adaptation to identify and systematically remove surface defects while preserving the canopy's optical properties and structural integrity. The robotic solution adapts in real time to handle the complex geometries and varying defect patterns encountered across different aircraft platforms.

"This contract represents a natural evolution of our physical AI technology into aerospace maintenance applications," said Dr. Satyandra K. Gupta, chief scientist and co-founder of GrayMatter Robotics. "The same adaptive intelligence that enables our systems to handle thousands of unique parts in manufacturing environments will now support the exacting requirements of optical surface restoration. We're essentially teaching robots to replicate and surpass the expertise of the skilled maintenance technicians."

Key technical innovations of the Smart Robotic Canopy Sanding System include:

- Autonomous Damage Detection: Advanced vision systems that identify and classify scratches, hazing, and other surface defects

- Adaptive Process Control: Real-time adjustment of sanding parameters based on material thickness, scratch depth, and optical requirements

- Quality Assurance Integration: In-process monitoring and documentation to ensure consistent repair quality and traceability

The system is designed to integrate seamlessly into existing depot- and field-level maintenance workflows, providing a scalable, data-driven approach to canopy repair that helps extend service life and improve aircraft availability across the Air Force fleet.

This latest AFWERX contract adds to GrayMatter Robotics' growing portfolio of defense and aerospace applications, following the company's selection as a winner in the U.S. Navy's Advanced Manufacturing Innovation for Maritime Readiness Challenge in August 2025.

The Phase II effort will include extensive testing and validation in collaboration with Air Force maintenance facilities, with initial prototype demonstrations planned for later this year. GrayMatter Robotics expects the technology developed under this contract to have broad applications across military and commercial aviation maintenance operations.