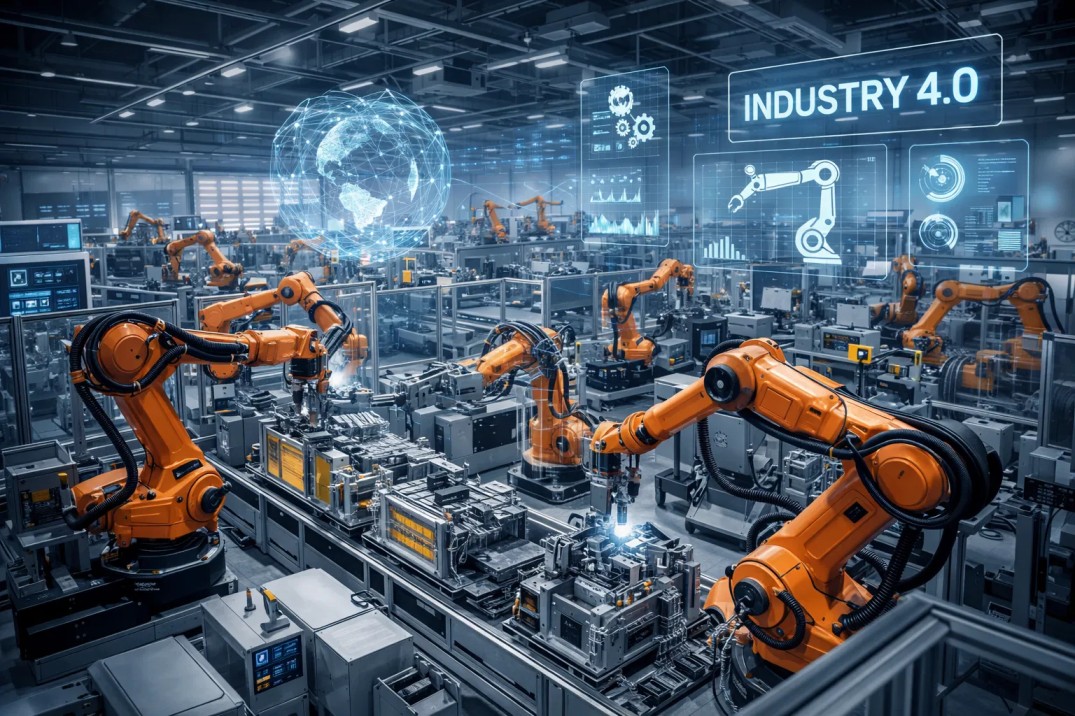

For decades, manufacturers have responded to their customers’ demands for increasingly complex products, which in turn typically increases complexity of designing and manufacturing those products.

And while complexity can seem daunting, we also have sophisticated new tools and information at our fingertips that empower us to thrive in this environment. Proliferation of data is the fuel that supercharges these tools. It’s the industry’s most valuable resource because it can do so much, when harnessed. But extracting data’s value is no small feat.

AI can help cut through the complexity. Imagine an AI assistant that flags supply chain risks. Simulations that push designers toward more sustainable and manufacturable designs. Automations that handle error-prone, burdensome tasks, freeing people to focus on high-value, more rewarding work. We’re building these capabilities, as well as empowering our customers to build them.

As an industry, we have an unprecedented opportunity to seize the value that AI, data, and digitization offer. To do so, we must start by accessing and interconnecting the data to uncover the insights it offers. 68% of data available for automation and insights goes unused because it’s disconnected, found Seagate Technology’s Rethink Data survey of global enterprise leaders. It’s sequestered in different tools, files, or silos, unable to inform the whole workstream and manufacturing ecosystem.

That’s why we’re so invested in continuing to build the Autodesk Fusion industry cloud. It’s the design and make platform for manufacturing. It’s a central environment for data, closely coupled with Autodesk AI to augment your creativity, automate your workflow’s tedious tasks, and analyze project data to yield predictive insights that benefit your business.

New Autodesk AI capabilities powering productivity and creativity

At this year’s Autodesk University (AU), I’m excited to share some of the ways we’re bringing new Autodesk AI-powered capabilities to Fusion, as well as Alias, that increase productivity as you design and make today’s complex products:

- AutoConstrain in Fusion Automated Sketching: Autodesk AI will analyze project sketches to detect intended spatial relationships between aspects of a design, such as symmetry, relative scale, and relationships between parts. It will then suggest dimensional constraints to maintain design intent through the entire project. And it adapts as you work, enabling you to edit or delete dimensions throughout your design process, then offering new options for a stable, predictable result. Automating this process saves significant time that a designer might spend manually defining these relationships, and prevents downstream delays created by intended constraints being overlooked.

- Drawing Automation in Fusion: With the click of a button, Drawing Automation examines 3D models and does the time-consuming work of generating the 2D drawings and dimensions required to manufacture parts. Autodesk AI will now accelerate and streamline this process even more by laying out drawing sheets for each component in a model, applying a style, and even identifying and removing fasteners that don’t need to be included in the drawing sets.

- Form Explorer coming to Alias: Autodesk AI will enable automotive exterior designers to generatively explore realistic new design forms and shapes in seconds. It will have the ability to learn from a brand’s historical styling language, generating designs that maintain those styling cues as a designer experiments with changes and instantly receives new iterations.

- Autodesk Assistant in Fusion: Powered by Autodesk AI, Autodesk Assistant in Fusion is an on-demand expert trained with both Autodesk-specific knowledge, such as Fusion’s capabilities, as well as general industry knowledge. Prompt the assistant with a question like, “How can I program my toolpath to avoid slot milling?” or “What manufacturing methods should I consider for this part?” and Autodesk Assistant will respond with Fusion-specific answers, or answers specific to manufacturing, and share hyperlinks to original sources.

EV pioneer Vayve Mobility’s entire design and make workflow completed in Fusion

Few markets are as competitive, and changing as quickly, as mobility and the automotive industry. At lightning speed, a new entrant needs to not only conceptualize, design, refine and iterate, engineer, produce and assemble the multitude of parts that comprise a car, addressing everything from electronics to suspension parts. It must also manage a complicated and fractured supply chain. All of these capabilities exist in Fusion, which led Vayve Mobility to choose Fusion as its solution for designing and making its two concept electric vehicles—the three-seat Eva and the five-seat CT5. Created in India with the unique needs of that market and environment squarely in its focus, Vayve’s vehicles have integrated solar panels to extend their range.

Vayve Mobility’s Eva prototype will be on display at AU this week, offering a close-up view of what a driven company can achieve when it chooses Fusion for its entire workflow.

Fusion’s growing capabilities and external connections

Built for connected workflows, Fusion has evolved beyond CAD and CAM to encompass CAE, ECAD, PLM, MES, and more. This year we’ve given Fusion the horsepower required by engineering teams who use it for complex projects with thousands of parts in their assemblies. At the same time, we’ve drastically increased its speed: many workflows now take less than half the time they used to; some feel instantaneous, running in less than 10% of the time they took last year.

And while Fusion itself grows in power and capability, extensibility is its true differentiator.

The new Manufacturing Data Model API

TThey’re announcing the release of a new Manufacturing Data Model API that enables our customers and partners to more easily exchange data with the cloud-hosted, granular data models that are the lifeblood of every Fusion project. With the new API, authorized third-party apps can now feed their data into Fusion models, better integrating Fusion with existing workflows, connecting it to cloud and desktop tools used across the industry.

Tools like OpenBOM, which created a web-based process that automates bill of materials (BOM) workflows, giving non-designers crucial views into a project’s BOM from the design data, removing a manual, mistake-prone process. And Cideon, which created a two-way connection between Fusion and SAP, enabling CAD engineers and manufacturers to see SAP’s enterprise resource planning (ERP) information in Fusion. This provides greater clarity about the components specified in a design, giving everyone up-to-date BOMs and common ground for follow-up ERP processes, such as calculating costs and ordering parts.

An ecosystem of connected tools for faster collaboration

We recognize that as our customers design and make, they rely on a broad ecosystem of tools that they expect to work together seamlessly. Autodesk partners with more than 150 hardware and software providers, more than 20 of which we added this year, to increase productivity, sustainability and speed to market with innovative products:

- Paperless Parts into Fusion: Integration of the Paperless Parts platform into Fusion enables manufacturing estimators to quickly generate quotes from the CAD models they receive from customers. Regardless of the file format of a model, the manufacturer can quickly identify potential manufacturing issues and use Fusion to make edits to improve a part’s manufacturability.

- Avnet into Fusion: The Avnet plugin empowers electronics designers to access a reference design library, as well as identify, research, cost, source, and procure components from within Fusion. The reference design library provides schematics and project descriptions that engineers can place directly into their designs, while access to Avnet’s supply chain expertise and data offers obsolescence planning, providing design assurance for manufacturability. This feature alone can greatly speed up a product’s time to market.

- Makersite into Inventor: The Makersite add-on, available now, brings sustainability insights to the product design phase in Inventor. Designers can calculate environmental and cost impacts of designs, view material replacement recommendations, heatmaps of sustainability trouble spots, and track progress toward sustainability goals as they make changes.

- NAVASTO into Alias Automotive: Autodesk has signed a definitive agreement to acquire NAVASTO, a company focused on the use of AI to accelerate design and engineering. The NAVASTO plugin would bring wind tunnel simulation into Alias’s early creative design process. It enables designers to predict and optimize the drag coefficient over an automotive exterior and its aerodynamics, reducing the likelihood of redesigns during engineering.

It’s an exciting time to be in the manufacturing industry.