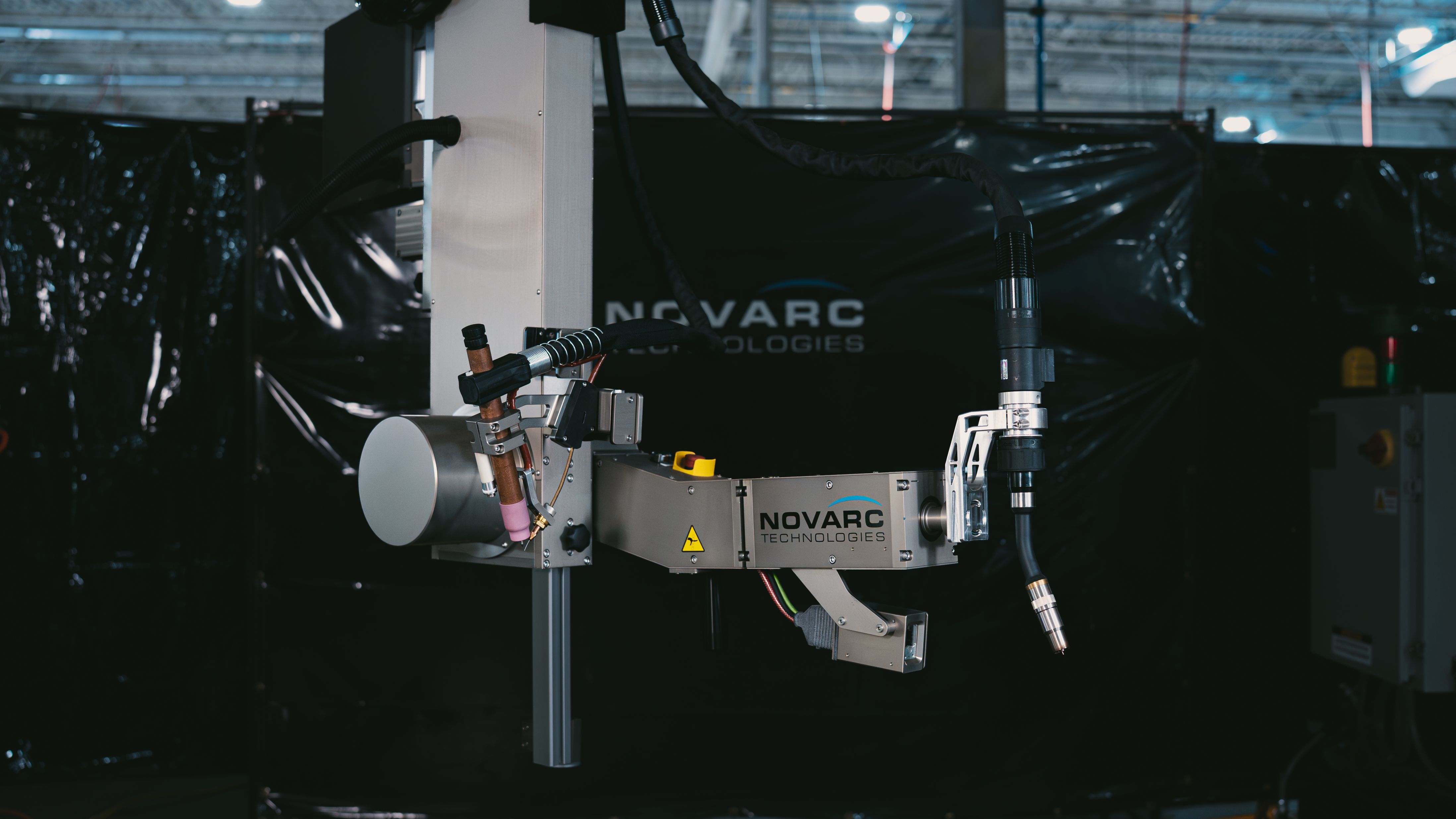

Novarc Technologies Launches SWR™-TIGMIG, the Industry’s First Dual-Process Spool Welding Robot Integrating TIG and MIG

The new autonomous platform combines TIG precision with MIG speed, delivering up to 4X productivity gains for fabricators requiring X-ray-quality welds and rapid throughput.

Image Courtesy: Public Domain

Novarc Technologies Inc. (“Novarc”), a full-stack AI robotics company pioneering automated welding solutions, announced the launch of the SWR™-TIGMIG, the industry’s first dual-process spool welding robot to integrate both TIG and MIG welding into a single, autonomous platform.

Designed for fabricators who demand X-ray-quality TIG root welds with the speed and throughput of MIG, the SWR™-TIGMIG sets a new standard for productivity and versatility in the pipe fabrication industry.

Novarc’s flagship SWR™, introduced in 2017 as the world’s first welding cobot, redefined shop-floor automation with MIG-based pipe and roll welding, delivering higher productivity, less than one per cent repair rates, and full automation. Building on that foundation, the new SWR™-TIGMIG now combines the proven speed of MIG with the precision of TIG, enabling up to 4X productivity gains on dual-process welds.

“SWR™-TIGMIG helps fabrication shops overcome complex welding requirements that have historically limited productivity,” said Joel Armstrong, Director of Product Management, Novarc Technologies. “By combining two systems into one, welders can perform precision TIG root passes and seamlessly transition to MIG fill passes in under 30 seconds, eliminating tradeoffs between quality and speed.”

The SWR™-TIGMIG is purpose-built for fabricators handling diverse projects that require uncompromising quality and rapid turnaround. With the ability to integrate up to four positioners, the system maximizes shop space while boosting throughput and reducing operating costs.

SWR™-TIGMIG offers a number of benefits to fabricators:

- Dual-Process in One System: TIG root welds with seamless transition to MIG fill passes in under 30 seconds.

- 4X Productivity Gains: TIG precision with MIG speed for unmatched efficiency.

- Flexible Shop Integration: TIG-only, MIG-only, or dual-process welding with a single system.

- Optimized Workforce Utilization: Reduced reliance on scarce skilled welders by ensuring consistent root and fill quality.

- Compact Footprint: The smallest in the industry at 4’ x 4’, the SWR™-TIGMIG is capable of integrating up to four positioners.

The SWR™-TIGMIG also provides many advanced features, including:

- Single-camera system with crystal-clear weld visibility and intuitive Luna UI providing seamless control over TIG and MIG with intelligent recipes and built-in process memory.

- Cutting-edge weld imaging system.

- Hot Filler Wire Technology.

- Patented TIP TIG Feeding System.

- NovData™ intelligent data and process management.

- NovSync™ advanced multi-positioner synchronization for maximum productivity.