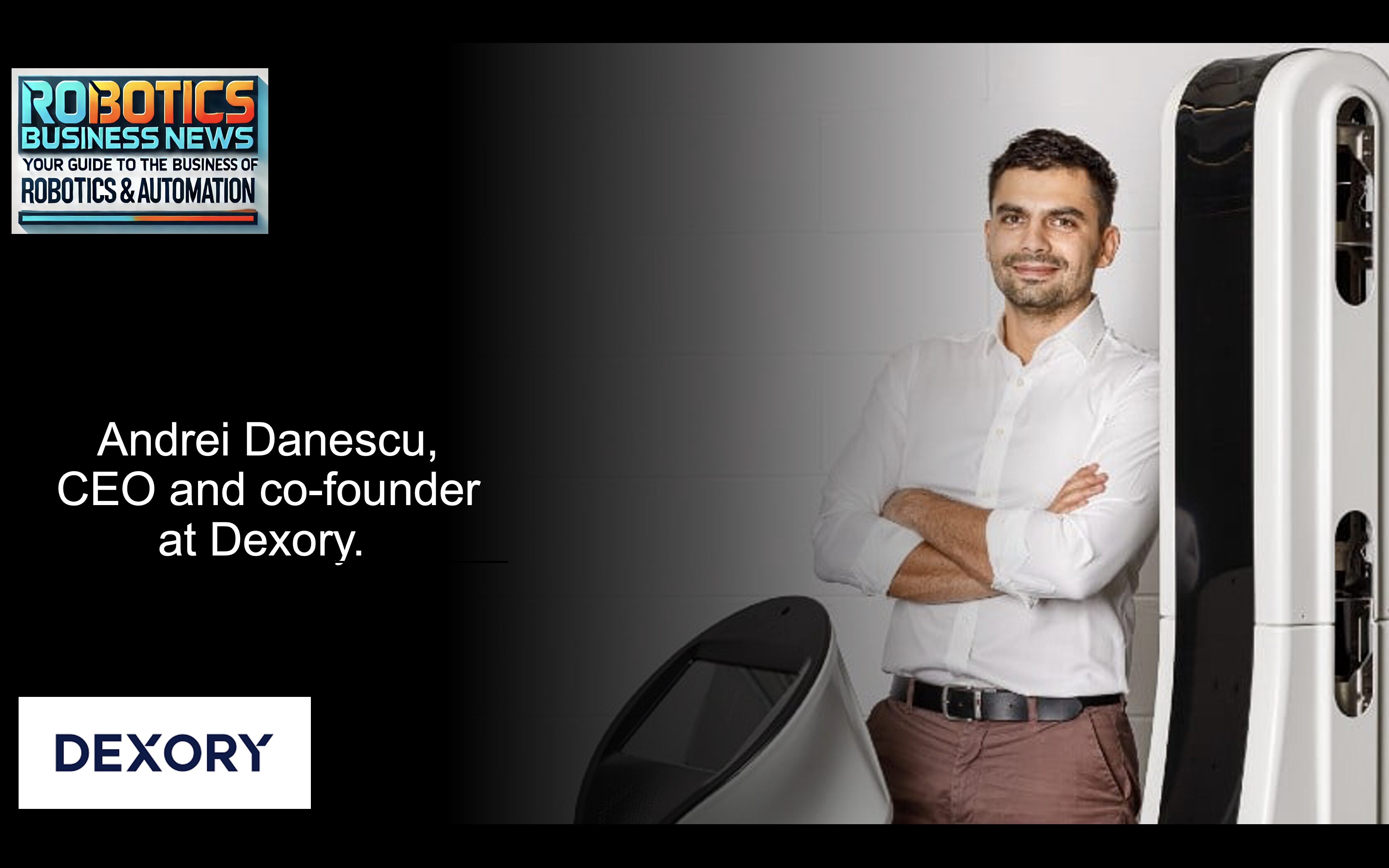

Inside Dexory’s AI Leap: Andrei Danescu on the Next Generation of Warehouse Optimization

26 March 2025 | Expert Insight | By editor@rbnpress.com

Dexory CEO and Co-founder Andrei Danescu breaks down how the company’s new optimization module is transforming warehouse operations with real-time insights, autonomous robots, and AI-driven planning.

As warehouses face growing pressure to operate faster, leaner, and smarter, Dexory is stepping up with a next-gen optimization module that’s redefining the game. Robotics Business NEWS sat down with Andrei Danescu, CEO and co-founder of Dexory, to explore how the new module—packed with features like slotting verification, congestion analysis, and predictive AI—helps businesses unlock higher productivity, accuracy, and space utilization. From real-world case studies to Dexory’s vision for a full-fledged warehouse operating system, Danescu shares what’s powering this transformation.

What are the key features of Dexory’s new optimization module, and how does it improve warehouse efficiency?

The new optimization module is designed to enhance warehouse efficiency through real-time data insights, predictive analytics and AI-driven decision making. Key features include outbound optimizer, slotting verification, consolidation planner, replenishment optimizer and congestion analysis. These features have been designed to provide further insight into the operation of the warehouse and make recommendations to ensure goods are easily accessible, items are stored in the right place, free up space, optimize faster stocking and identify bottlenecks.

How does this module integrate with existing warehouse management systems and automation solutions?

DexoryView has been designed to integrate with WMS systems to ensure warehouses have a holistic view of the true state of the warehouse. This approach allows for continuous monitoring of the health and hygiene of the warehouse, whilst allowing operators to make strategic decisions based on real-time data to drive their businesses forward.

What role does AI play in the functionality of this optimization module?

AI is the backbone of DexoryView and it’s not different for the new optimization module. We deploy autonomous mobile robots in warehouses to capture data and our robots process 4GB of data per meter. This provides real-time AI-powered recommendations to businesses on how to best optimize their warehouse layout, allowing them to operate more efficiently and make sure they are utilizing their warehouse space appropriately.

Can you share any case studies or pilot programs that demonstrate the module’s impact on productivity and cost savings?

While the module is new to the market, we have been working with our customers to introduce and develop these functionalities. All in all, DexoryView has allowed customers to improve their warehouse accuracy significantly. For example, an online furniture retailer moved from 92% accuracy to 98% accuracy in just three days. We have customers that have been able to save up-to 80hours per week on making sure their warehouse integrity is maintained. In addition to these achievements, our customers are also upskilling their staff. A customer specialising in logistics services to the pharmaceutical industry is using the time freed to upskill their staff to become data analysts, which will help them drive their business forward.

What challenges in warehouse operations does this technology specifically address?

The Optimization module has been designed to address critical challenges in the warehouse, including inefficient space utilisation, reduce time intensive labor processes and dynamically assess tasks and optimize picking routes. In combination with the Integrity module, DexoryView reduces inventory inaccuracies, through leveraging real-time data capture, which prevents stock shortages or overages.

How does Dexory’s solution compare to other warehouse optimization technologies currently available in the market?

Traditionally, optimization technologies rely on static rules and periodic manual updates. The DexoryView Optimization module combines AI-driven insights with real-time data capture that is visualized on a digital twin platform. This provides a more holistic and adaptable approach, ensuring that warehouses can react instantly to disruptions and optimize workflows proactively rather than reactively.

What are the future plans for Dexory in expanding its automation and AI-driven solutions for the logistics industry?

Dexory is committed to pushing the boundaries of AI-driven warehouse optimization. Future plans include expanding the capabilities of the DexoryView platform to include more AI-powered features that will help transform the solution into a true warehouse operating system that allows businesses to not just make data-driven decisions, but orchestrate their warehouse automations.