University of Queensland Researchers Develop Animal-Inspired 3D Printing Technique for Advanced Medical Robotics

Breakthrough 3D printing method combines liquid metal nanoparticles and gallium-based nanorods to mimic animal physiology, paving the way for advanced medical robotics and rehabilitation devices

University of Queensland researchers have unveiled a groundbreaking 3D printing method that mimics animal physiology to create liquid metal robotics with musculoskeletal qualities. This innovative approach could revolutionize medical rehabilitation devices by combining strength, flexibility, and adaptability.

Dr. Ruirui Qiao and her team at the Australian Institute for Bioengineering and Nanotechnology (AIBN) have successfully developed shape-shifting gallium-polymer composites inspired by the efficient and controlled movement of mammals.

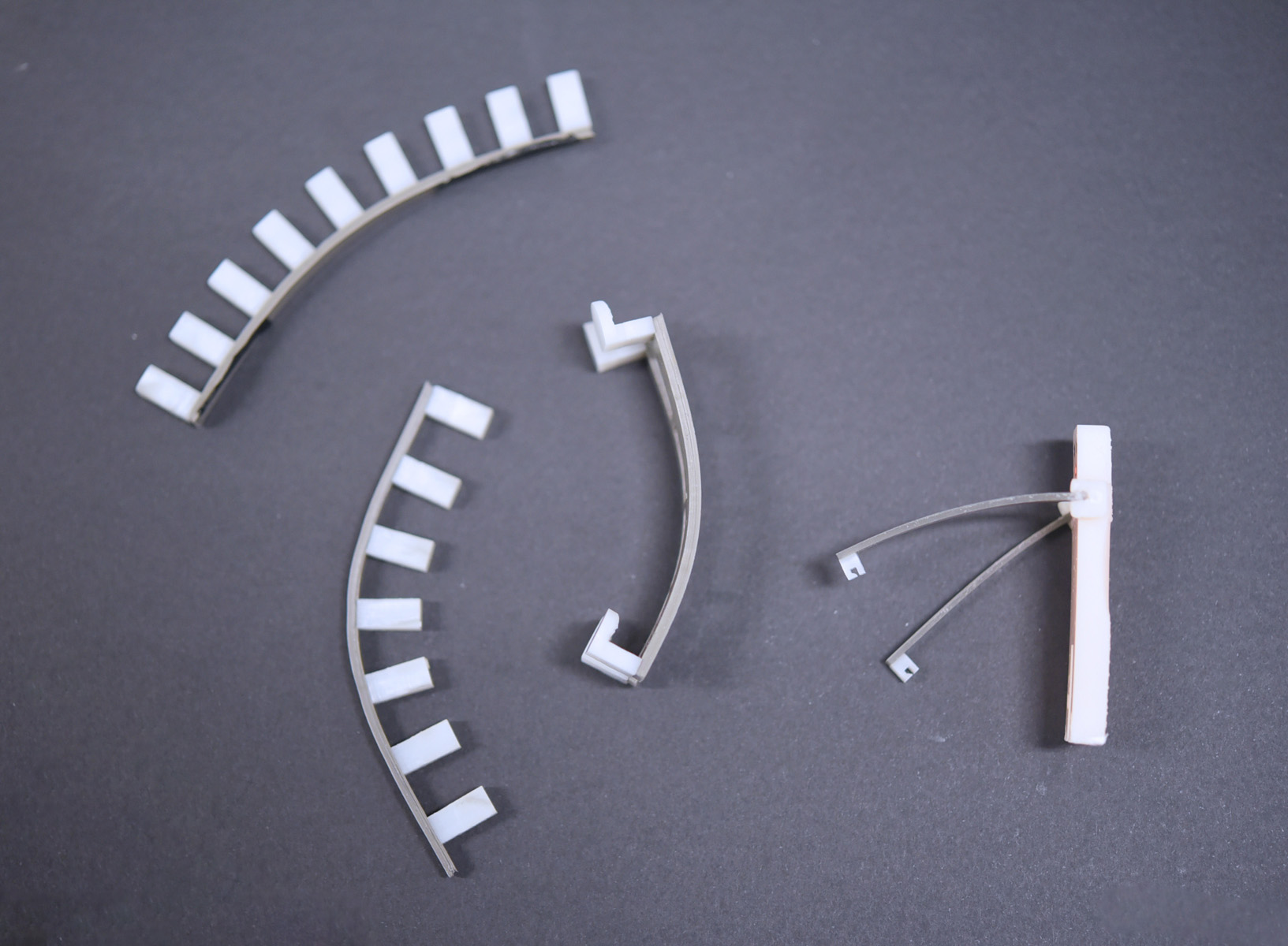

“We set out to mimic the locomotion, flexibility, and control of mammalian movement,” said Dr. Qiao. “By combining soft spherical liquid metal nanoparticles with rigid rod-like gallium-based nanorods in the 3D printing process, we’ve created an interconnected network akin to bone and muscle. This unique material design offers superior strength and flexibility for next-generation medical rehabilitation devices.”

The tuneable gallium-polymer composite has potential applications in creating high-precision components, such as grippers for prosthetic limbs. These hybrid materials can take and retain various shapes and functions when exposed to stimuli like heat or infrared light, enabling advanced customization and functionality.

Dr. Qiao highlighted the challenges traditional manufacturing faces in replicating such hybrid structures. “Nature often inspires soft robotics, but material limitations and complex multi-step manufacturing hinder progress. Our new 3D printing method simplifies this process, paving the way for practical and transformative innovations.”

The ease of fabrication and adaptability of these materials promise to revolutionize hybrid soft materials and soft robotics. Future research aims to enhance the responsive properties of the gallium-polymer composite by increasing the proportion of metal-based nanoparticles.

“This advancement in 3D printing technologies and material design could significantly improve the performance of hybrid soft robots, offering new solutions for medical and industrial applications,” Dr. Qiao added.

The research team, including Xumin Huang, Jiangyu Hang, Naufal Kabir Ahamed Nasar, Thomas Quinn, Dr. Liwen Zhang, and Professor Tom Davis, has published their findings in the prestigious journal Advanced Materials.