Mitsubishi Electric Introduces Breakthrough Physics-Embedded AI to Predict Equipment Degradation With Minimal Data

Mitsubishi Electric’s new Neuro-Physical AI technology, developed under its Maisart® program, delivers highly accurate equipment-health estimation using limited training data—helping manufacturers boost productivity, enhance reliability, and reduce maintenance costs amid Japan’s shrinking skilled workforce.

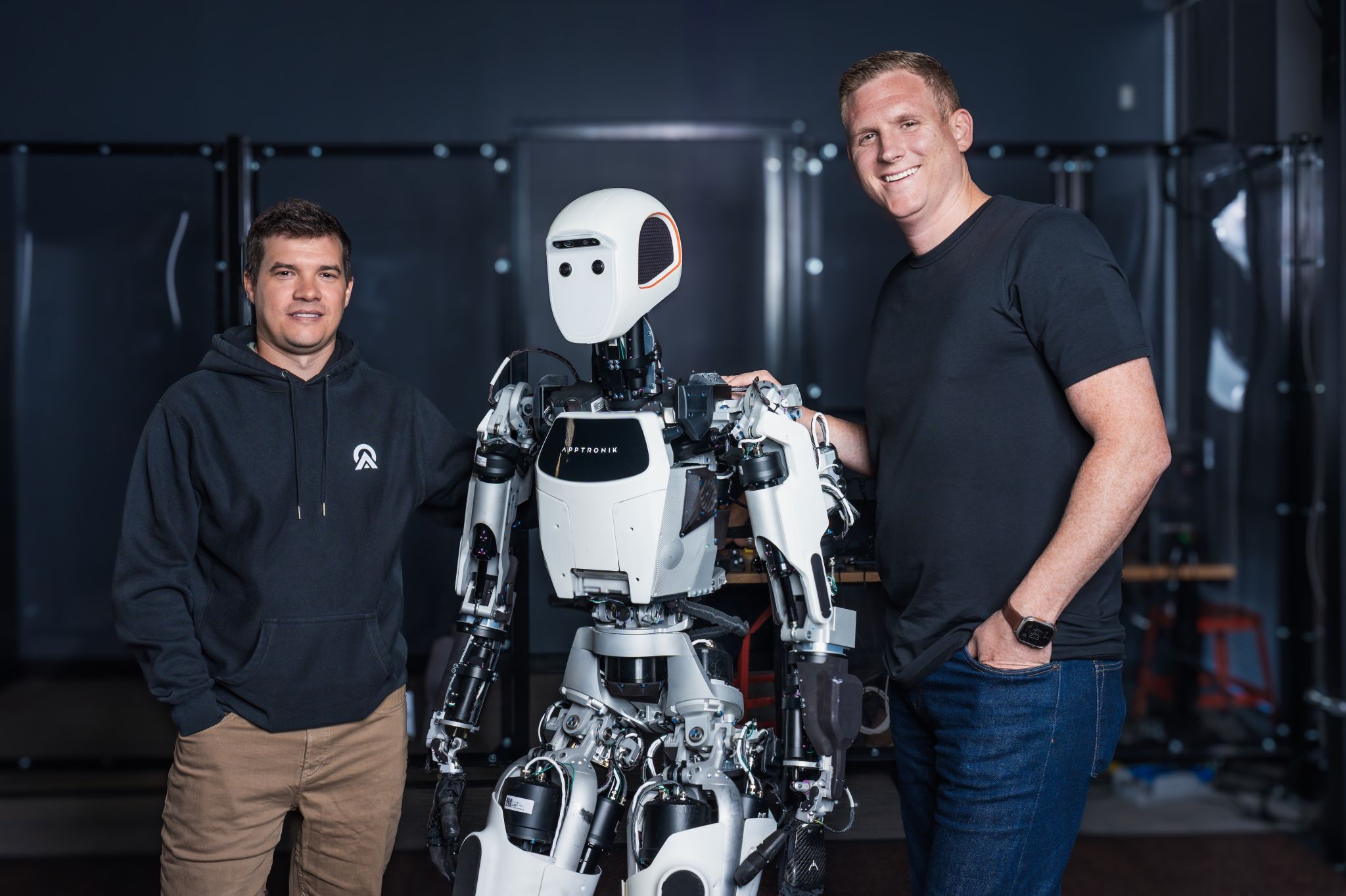

Image Courtesy: Public Domain

Mitsubishi Electric Corporation announced that it has developed a physics-embedded AI that can accurately estimate equipment degradation using minimal training data. The technology is an outcome of the company’s Neuro-Physical AI initiative within its Maisart® AI program, which emphasizes reliability and safety in the physical world. Leveraging Mitsubishi Electric’s extensive equipment-development expertise, the new technology supports the optimization of manufacturing-site assets to maintain productivity and quality as well as reduce maintenance costs.

Japan’s manufacturing sector is deploying increasingly sophisticated production equipment at a time when the nation’s aging and shrinking population is reducing the number of experienced maintenance technicians. Meanwhile, there is a growing demand for preventive-maintenance solutions that can predict equipment degradation for timely responses, since continued use of degraded equipment can result in equipment failure or defective products. Conventional preventive maintenance typically mimics equipment behavior using mathematical models or simulations to estimate degradation. But this approach requires domain experts with knowledge of physical systems to design degradation-detection mechanisms from scratch, which can require significant time and effort. To address this issue, there is a movement to estimate degradation by training AI with operational data. However, these efforts typically require vast amounts of data to comprehensively cover diverse operating patterns, unit-to-unit variability and installation environments, as well as retraining whenever conditions change, hindering the practical deployment of AI to estimate equipment degradation.