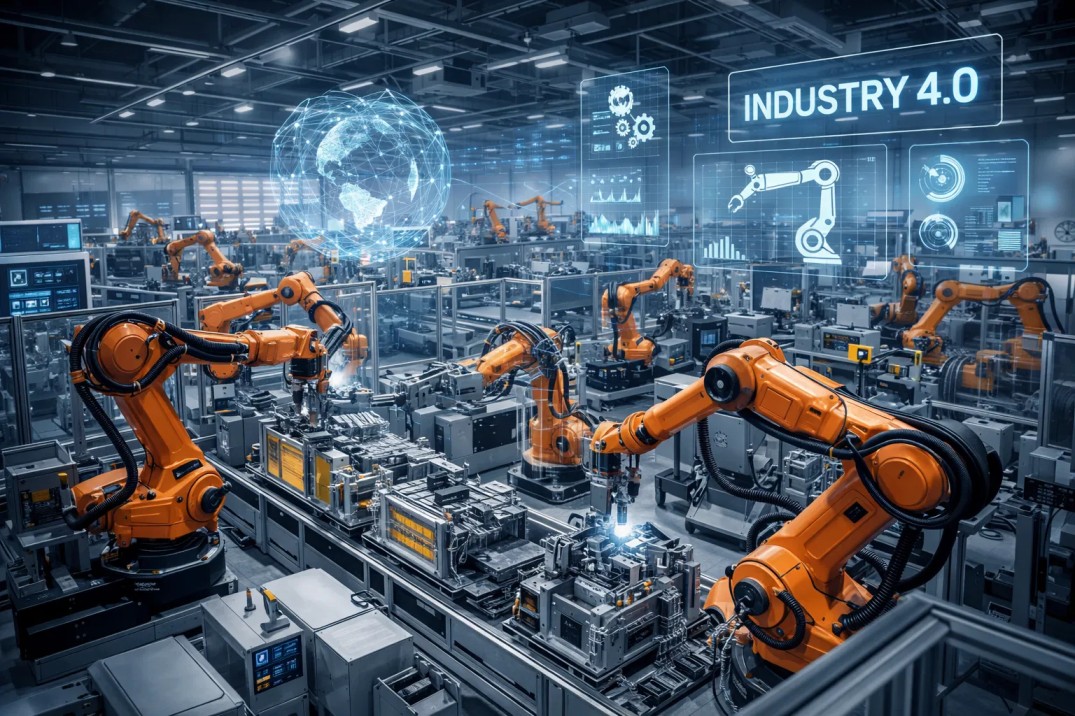

Dozuki Partners with TWI Institute to Revolutionize Manufacturing Workforce Training

Combining TWI's proven Job Instruction methodology with Dozuki's advanced digital platform, this collaboration creates a powerful solution for upskilling and retaining frontline workers, boosting efficiency, safety, and productivity across manufacturing operations.

Image Attribution: Public Domain

Dozuki, the leading manufacturing Connected Worker Platform, is pleased to announce a strategic partnership with the TWI Institute, a global leader in Training Within Industry (TWI) methodologies. This collaboration aims to revolutionize the way manufacturers and industrial companies develop and train their frontline workers, bringing together the proven training methods of TWI Institute with the advanced Dozuki digital platform.

This partnership leverages the strengths of both organizations to create a comprehensive solution for workforce development, addressing the pressing challenges faced by manufacturers in upskilling their employees. With the TWI Job Instruction (JI) methodology and the Dozuki digital platform, companies can now implement standardized digital training programs that ensure efficiency, quality, and safety across their operations.

Patrick Graupp, Owner and Senior Master Trainer for the TWI Institute, shared his excitement about the partnership:

"At the heart of TWI is the Job Instruction method, which has been proven for decades to help companies develop a skilled and stable workforce. Partnering with Dozuki allows us to combine our time-tested training methodology with cutting-edge technology, giving companies the tools they need to not only train their workers but also track progress and continuously improve performance."

The Dozuki platform provides seamless support for the TWI Job Instruction Breakdown (JIB), enabling manufacturers to digitize and manage training procedures, creating a streamlined path from awareness to mastery. By integrating TWI methodology into Dozuki, companies gain the added benefits of document control, ensuring that all training documentation is tracked with full revision control and audit trails. This feature is particularly valuable for TWI Certified Trainers, who can now ensure their materials are always up-to-date and accessible.

The partnership also delivers tangible business results:

- Training Time: Companies have seen a 78% reduction in training time, accelerating the onboarding process and getting workers up to speed faster.

- Productivity: A 45% increase in productivity has been achieved, driving more efficient operations and better use of resources.

- Safety: In manufacturing, the partnership has contributed to reducing OSHA incidents by as much as 70%, fostering a safer work environment.

- Turnover: Employee turnover has been reduced by 23%, helping companies retain skilled workers and reduce the costs associated with high turnover rates.

Early adopters of this integrated solution have reported significant improvements:

- 75% reduction in time-to-competency for new hires

- 40% increase in overall productivity

- Up to 65% decrease in quality-related issues

- 20% improvement in employee retention rates

Jerry Dolinsky, CEO of Dozuki, highlighted the value this partnership brings to the industry:

"Our collaboration with TWI Institute is a game-changer for manufacturing workforce development. By aligning our digital platform with their proven training methods, we can help companies address some of their biggest challenges — reducing training time, increasing productivity, and improving safety outcomes. Together, we are creating a standardized, scalable solution for companies to develop and retain a skilled workforce."

The partnership addresses key issues that manufacturers face today, such as high turnover, inconsistent quality, and rising safety concerns. By implementing the combined solution of hands-on TWI training and digital management tools in Dozuki, companies can ensure that their workers are not only trained efficiently but are also empowered to continuously improve their performance.