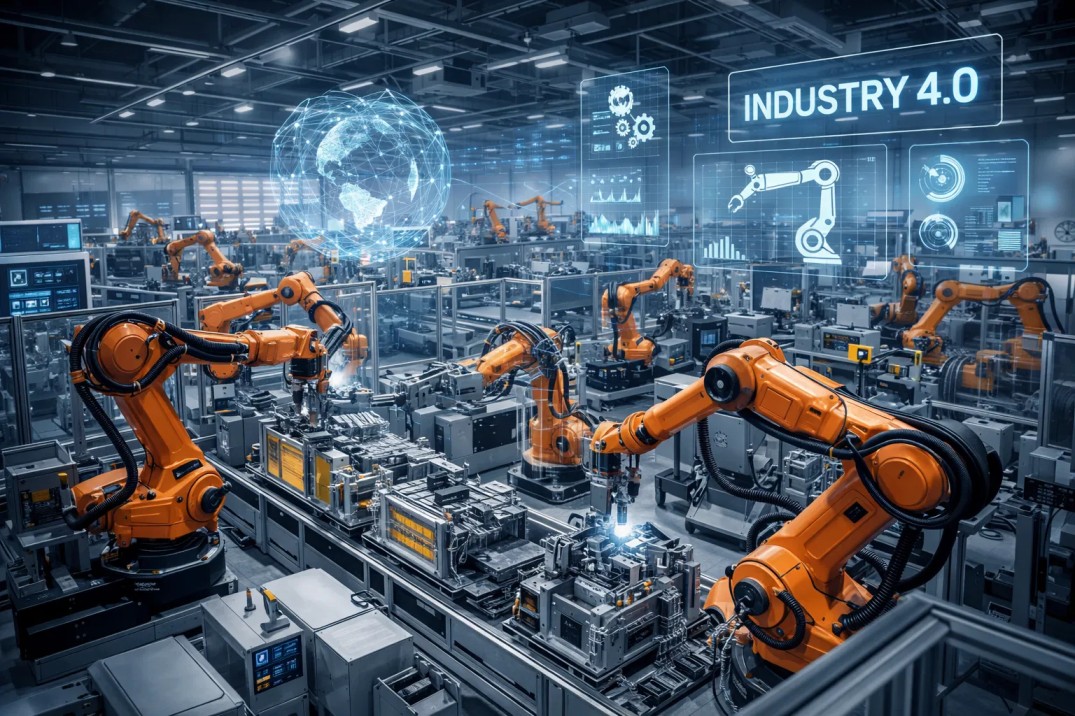

Vecna Robotics Unveils CaseFlow™: Transforming Case Picking with Pallet-Handling Robots and Dynamic Zone Orchestration

CaseFlow™ doubles warehouse performance by automating up to 90% of travel with pallet jack robots and optimizing worker tasks through advanced orchestration software. Piloted with GEODIS, the solution enhances productivity, safety, and employee satisfaction, offering a fast ROI and seamless integration with leading Warehouse Management Systems.

-Vecna Robotics, the leader in flexible material handling automation solutions, today introduced CaseFlowTM, an end-to-end solution for case picking operations that uses pallet-handling robots for up to 90% of warehouse travel and orchestrates workers with dynamic, directed zone picking, more than doubling site performance while improving worker satisfaction and safety.

According to data from Logistics Management and Warehouse & Distribution Science, case picking comprises nearly half of all work in warehouse and distribution facilities, and up to 90% of that work can be made more efficient via automation, including travel time and paperwork. No wonder 45% of warehouse operators are looking to automate this workflow right now, according to a 2020 study in Forbes. Vecna estimates that the current size of the North American case picking market primed for automation is $10B annually.

Vecna Robotics CaseFlowTM redefines case picking for mid- to high-volume warehouse operators in retail, 3PL distribution, consumer packaged goods, food and beverage, and medical supplies. The solution orchestrates a fleet of Vecna Robotics CPJ pallet jack robots that perform all of the pallet-based travel in the warehouse and directs human pickers, equipped with connected wearables, with tasks generated from the site's existing Warehouse Management System (WMS). Powered by Vecna’s cutting-edge PivotalTM orchestration software, CaseFlowTM continuously prioritizes orders and optimizes robot routes and picking tasks. Using fewer workers than traditional manual operations, CaseFlowTM dynamically adjusts worker picking zones to keep goods flowing and maximize units picked per hour (UPH).

Over the past 18 months, Vecna Robotics has worked with GEODIS, a world leader in transport and logistics, to develop a solution that could increase their case picking productivity by automating both robot travel and human work. Since fully deploying CaseFlowTM at its Indianapolis pilot site, GEODIS has more than doubled workflow productivity with no reported safety issues.

“The warehouse segment is facing chronic labor shortages, and case picking is the most labor-intensive operation at many of our sites,” said Andy Johnston, Senior Director of Innovation at GEODIS. “By implementing CaseFlowTM with Vecna’s robots, we were able to increase picking efficiency by over 100% while improving worker retention and overall safety. We look forward to scaling this solution across our network and continuing to collaborate with Vecna Robotics on automating our most critical workflows.”

CaseFlowTM is now available to the market as an annual subscription service that lowers the cost of entry and enables operators to focus on optimizing case picking throughput and redirecting labor to more critical workflows in the warehouse.

“Warehouses and distribution center operators have struggled to automate this critical workflow because solutions like conveyors and automated storage and retrieval systems are either too expensive, disruptive, or inflexible,” said Michael Helmbrecht, COO and SVP of Product at Vecna Robotics. “In the case of semi-autonomous robots and sled AMRs, operators have historically realized limited throughput gains because these solutions don’t orchestrate the entire workflow. That all changes with CaseFlowTM.”

Vecna Robotics CaseFlowTM offers the following benefits to operators within both existing and greenfield case picking operations:

- Doubles worker UPH: Dynamic, directed zone picking removes the need for manual driving resulting in more than 2x performance improvement in units picked per hour through orchestration of both human and robotic work.

- Short ROI payback: With reduced picking workforce required to handle daily volumes, ROI payback is less than 12 months through innovative Robots as a Service pricing.

- Fast to implement, low disruption: Less than 4 weeks to implement and a 50% reduction in new employee training time (vs. traditional operations) with minimal up-front investment and no disruption to existing operations; hot swappable robot batteries maintain continuous goods movement.

- Full on-site control: CaseFlowTM Console delivers full control with real-time telemetry and performance data, empowering operations managers to monitor order releases, associate behaviors, and robot status in real-time. It also enables industrial engineers and site managers to identify bottlenecks for future optimizations.

- WMS interoperability: Provides seamless operation through native compatibility with leading WMS’ from Manhattan Associates, Korber, Blue Yonder, SAP, Oracle, Tecsys, and others.

- Improved safety: Travel-related safety incidents are virtually eliminated with no need for associates to get on and off trucks, having them focus exclusively on picking-to-order.

- Enhanced employee experience: Increased associate satisfaction, safety, and productivity through less rigorous working conditions, resulting in higher employee retention.

- 24/7 remote monitoring: As with all Vecna Robotics workflow solutions, CaseFlowTM benefits from remote monitoring and available intervention from Vecna Robotics 24/7 PivotalTM Command Center.