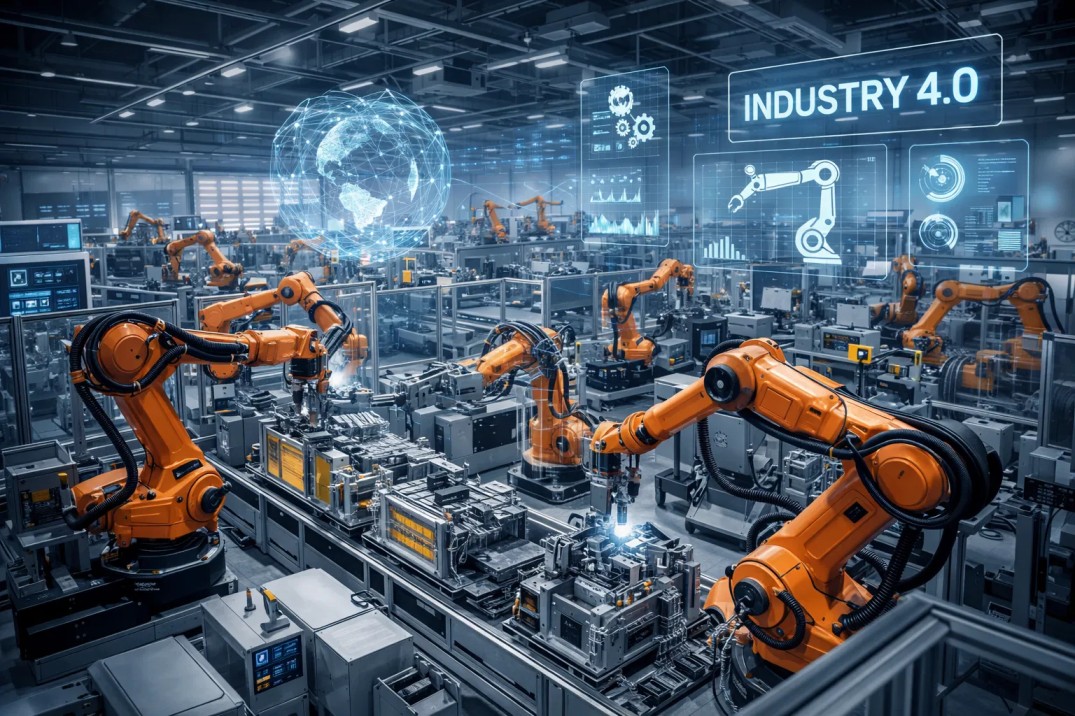

Comau Delivers Fully Automated Assembly Line for JMC Ford’s Premium Pickup Production

100% Automated Welding Solution Powers 3+1 Multi-Vehicle Production Line with an Annual Capacity of 125,000 Units, Ensuring Flexibility, Precision, and Future Expansion at Xiaolan Plant.

Image Source : Public Domain

• Comau has designed and developed a fully automated assembly line to produce premium pickup truck models at the JMC Ford Xiaolan plant

• The highly flexible welding automation solution has enabled 3+1 multi-vehicle co-production line with a 100% automation rate

• The project implemented the mainline and the floor line, achieving an annual capacity of 125,000 units

• The advanced solution addresses current production needs while laying a solid foundation for future expansion

Comau has designed and deployed a flexible and comprehensive Body-In-White (BIW) manufacturing solution for JMC Ford to produce high-end pickup trucks at the Xiaolan plant in China’s Jiangxi province. The project established a highly versatile production line capable of accommodating various models and configurations, including JMC Ford’s new pickup truck brand Da Dao (Avenue) and Ford’s first pickup truck model introduced in the Chinese market, the Ranger. The fully scalable, state-of-the-art solution delivers a 100% automation rate while ensuring the vehicle quality and performance JMC Ford is known for, positioning JMC Ford to better address the growing demand for diversified and personalized products.

Comau’s body-in-white welding solution improves welding accuracy and stability, thus ensuring the final product’s structural integrity and safety. The solution also optimizes production processes and includes the adoption of advanced automation technologies to enhance production efficiency, reduce cycle times and increase output. And by incorporating both the welding and tightening guns within an integrated system. Comau was able to minimize the need for frequent tool changes. The solution also leverages advanced vision inspection technology for better quality control and allows JMC Ford to reduce their equipment investment and maintenance costs.

The flexible and removable fixture loading table that Comau developed for the project can be easily reconfigured for different assembly tasks and parts. This design reduces line changeover times, reduces tooling investments, optimizes workflow, and improves product quality. Moreover, the comprehensive manufacturing set-up also features Comau’s OpenGate system, which ensures geometrical accuracy while granting inherent flexibility with an aggressive average switching cycle time of just 50 seconds.

“Our goal was to create a more efficient, reliable, and flexible production line for the rapidly expanding pickup truck market, and we have achieved impressive outcomes. Partnering with Comau marks an important milestone in our journey toward manufacturing excellence. Comau’s innovative approach and commitment to quality provide us with a solid foundation, paving the way for future advancement and continued success”.

Ma Jian, JMC Ford Head of Manufacturing Engineering

“Thanks to the strong collaboration between our engineering teams, Comau has helped JMC Ford meet its quality and precision requirements, and streamline overall capital expenditure.The collaboration has also allowed us to achieve a high level of automation and flexibility while laying a solid foundation for future expansion.”

Jeff Yuan, Comau APAC Countries Cluster Leader