ABB Secures Top Honor at Euromines Safety Awards 2024 for Automated Robotic Blasting Technology

ABB’s collaboration with Swedish mining companies and explosive suppliers revolutionizes underground safety by automating high-risk blasting tasks, earning recognition for advancing health and safety standards in mining.

Image Source | Public Domain

- ABB collected top award at the Euromines Safety Awards 2024 ceremony in Brussels

- Automated robotic loader and charger for the blasting process has been developed with Swedish mining companies Boliden and LKAB, and explosive suppliers Forcit and LKAB Kimit

- By automating a manual task and removing workers from high-risk blasting zones, the technology is creating a safer environment

ABB has been recognized for its outstanding commitment to health and safety in the mining industry with a Euromines Safety Award 2024, presented at a ceremony in Brussels on Wednesday, October 2, 2024. The top honor was given for ABB’s technology demonstrator, an automated robotic remote blasting loader and charger developed for use in underground mines, in collaboration with Boliden and LKAB, and explosive suppliers Forcit and LKAB Kimit.

The second annual edition of the awards, organized by the European Association of Mining Industries, Metal Ores and Industrial Minerals (Euromines), attracted dozens of applications from member companies and institutions around the world. On the awards night, three were chosen for honors out of 12 finalists, with ABB taking home the gold prize.

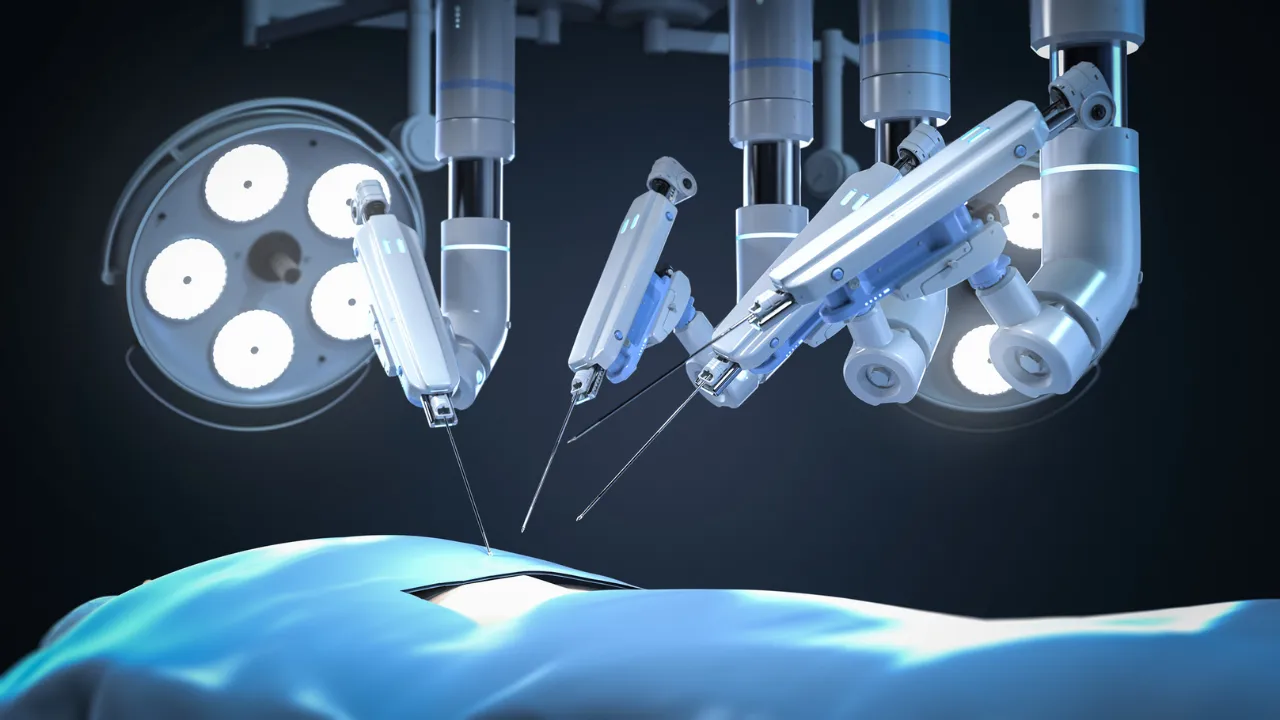

The objective of ABB’s robotic loader and charger is to make mines safer by automating one of few manual processes left in mining: charging the blasting holes with explosives. This is a process that can take place up to 15 times per day in larger mines as miners expand the chambers to extract mineral and metal ores. The technology automatically detects boreholes and fills them with explosives without the presence of workers, removing the need for people to be near the unsupported rock face during loading and charging sequences.

The technology comprises of the main ABB industrial robotic arm mounted on a carrier vehicle with integrated bulk emulsion and vision systems and a second robot arm to assemble prime and detonator. It is an automated solution that ensures full reach to all borehole levels and areas of the rock face and remote control for operators.

“ABB’s dedication to maintaining a safe workplace is a credit to the mining industry and we commend the team for their ongoing efforts,” said Rolf Kuby, Director General of Euromines. “We thank all participants for their endeavors and look forward to continuing to use technologies and best practices to improve the mining industry daily.”

“While productivity and sustainability are lauded for propelling the mining industry forwards, safety is the key driver, it is always number one,” said Max Luedtke, Business Line Manager for Mining, ABB Process Industries. “For ABB, solutions in engineering and through industry-specific technologies are how we make real progress. Having the automated robotic remote loader and charger recognized by our peers for the true difference it can make in removing people from harm’s way while maintaining productive operations is an honor. We want to thank our partners in that journey, Boliden and LKAB, Forcit and LKAB Kimit. This is an award for all who have contributed to the concept becoming a reality.”

The annual awards ceremony recognizes contributions by Euromines member companies towards enhancing health and safety in the European mining sector. An independent jury, composed by experts from EU circles, assessed the application projects based on the criteria of innovation, impact, practicality and financial impact.

ABB joined Euromines in December 2023. Euromines serves as a cooperative network of members focused on sharing responsible raw material mining practices. It also evaluates the impact of European and international policies and legislation on the industry and defines industry policy positions and actions. It represents large and small companies and subsidiaries in Europe and in other parts of the world. It previously launched the Sustainable Mining Initiative in which members share insights on circular economy, nature restoration, decarbonization and community. It provides services to members with regard to EU policy and serves as a network for cooperation and for the exchange of information throughout the sector within Europe. The association also fosters contacts with the mining community throughout the world. Euromines represents an interface between the European extractive industry and the European authorities and international or intergovernmental bodies and advocates the extractive industry.

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation.