Zebra Technologies Showcases Breakthrough Intelligent Automation Solutions at Automate 2025

From AI-powered AMR picking to next-gen 3D vision and RFID tracking, Zebra unveils cutting-edge tools to transform manufacturing and warehouse productivity through greater visibility, precision, and speed.

Image Courtesy: Public Domain

Zebra Technologies Corporation, a global leader in digitizing and automating frontline workflows, announced that it is presenting its newest solutions to advance intelligent automation across manufacturing and warehouse operations. Zebra’s portfolio is being showcased in Booth 3207 at Automate 2025 on May 12-15 at Detroit’s Huntington Place.

“Visibility is the first step to transformation, and the adoption of AI and intelligent automation enables manufacturers and warehouse leaders to leverage data more effectively to identify, react, and prioritize problems and projects, delivering new efficiencies for maximum impact,” said Andy Zosel, Senior Vice President and General Manager, Intelligent Automation, Zebra Technologies. “Zebra empowers the frontline with solutions that increase productivity and throughput to an unprecedented level.”

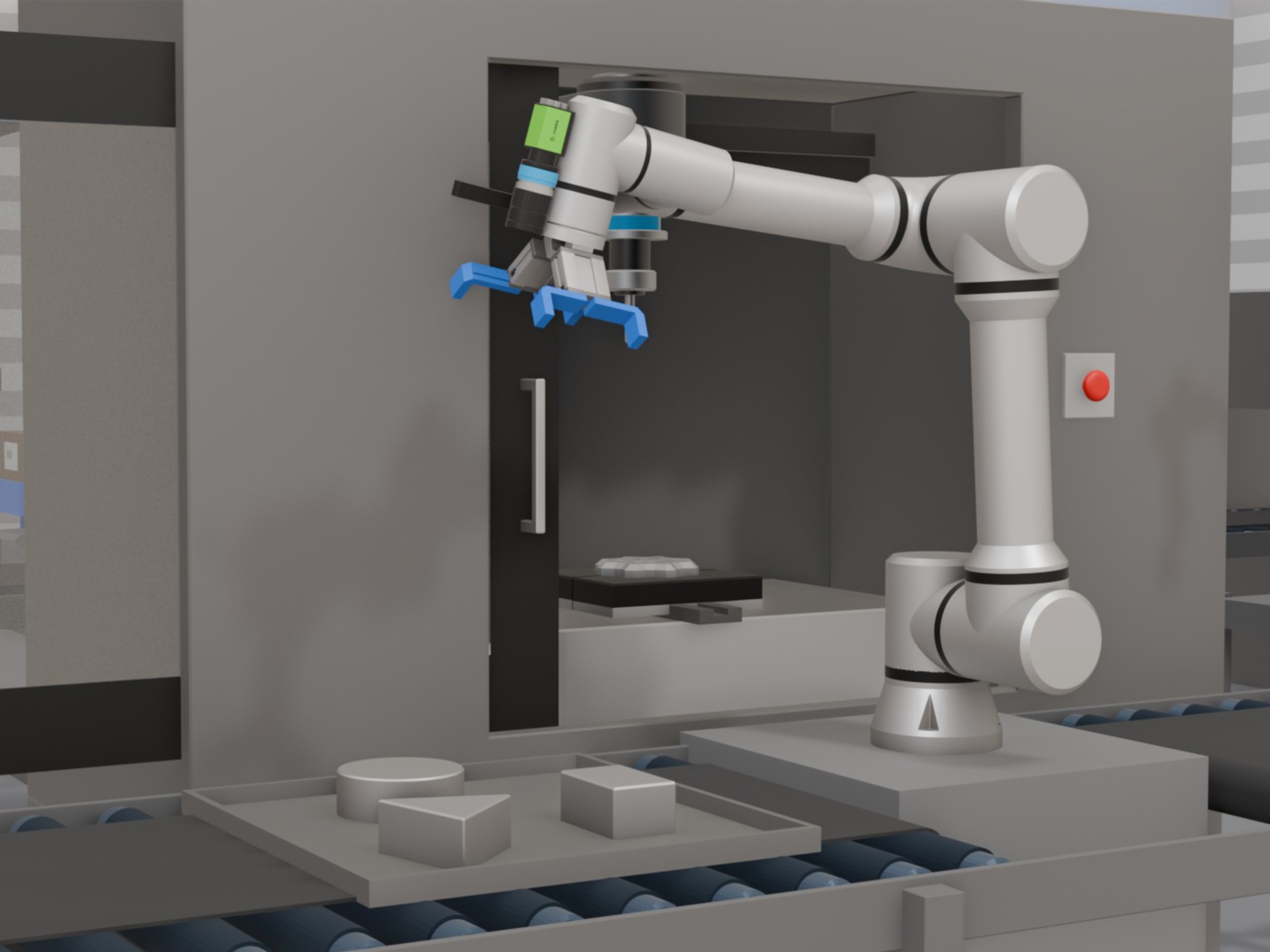

One solution designed to drive frontline productivity is Zebra‘s new Aurora VGR Assistant, a software add-on tool for Zebra’s Aurora Design Assistant software. It simplifies the configuration and deployment of vision-guided robotics (VGR) tasks with leading collaborative robotics solutions. This software targets common VGR applications such as machine tending, packaging, and guiding assembly tools. Aurora VGR Assistant leverages Zebra’s machine vision software to simplify the integration of 2D robot guidance and machine vision inspection tasks in a single software platform.

Zebra Symmetry Fulfillment is the latest comprehensive AMR-assisted-picking solution utilizing Zebra Connect Fulfillment AMRs, wearable technologies, software, and analytics designed to increase productivity and reduce costs in warehouse operations. This AI-powered solution combines the functions of a warehouse execution system (WES) with robot fleet management and powerful analytics. It enables workers to load and unload orders to and from carts without requiring the AMR to remain permanently attached to each cart, increasing utilization and reducing by up to 30% the number of AMRs needed versus legacy systems.

At Automate, Zebra is also highlighting the AltiZ 4200 3D profile sensor which is built to deliver tight fields of view in a compact form factor along with ultra-high resolution. It features significantly more data points per profile and faster capture speeds to address challenging inspection tasks with quality assurance in electronics and automotive manufacturing applications.

In addition, Photoneo, now part of Zebra Technologies, is presenting its MotionCam-3D (Blue), an advanced 3D VGR solution in the Zebra booth. The MotionCam-3D (Blue) delivers breakthrough improvements in key 3D sensing capabilities, leveraging Photoneo's Bin Picking software for robot guidance to enable precise picking of metal parts at various depths in a more efficient and accurate way. Mounted on a robotic arm in hand-eye position, the MotionCam-3D (Blue) provides superior scanning performance through virtually unlimited multi-angle scans. As the arm moves, the sensor captures a continuous, high-fidelity 3D data stream to build complete scene models in real time.

Automate visitors can also experience Zebra’s RFID interactive demo which tracks customer orders from incoming goods at the receiving bay to the outbound shipments dock. This solution showcases how frontline workers can save time and deliver more accurate counts through inventory audit and order picking with Zebra’s MC3390xR, a best-in-class, long-range, Android™-based RFID reader along with the picklist verification process via Zebra’s FXR90 ultra-rugged RFID reader.

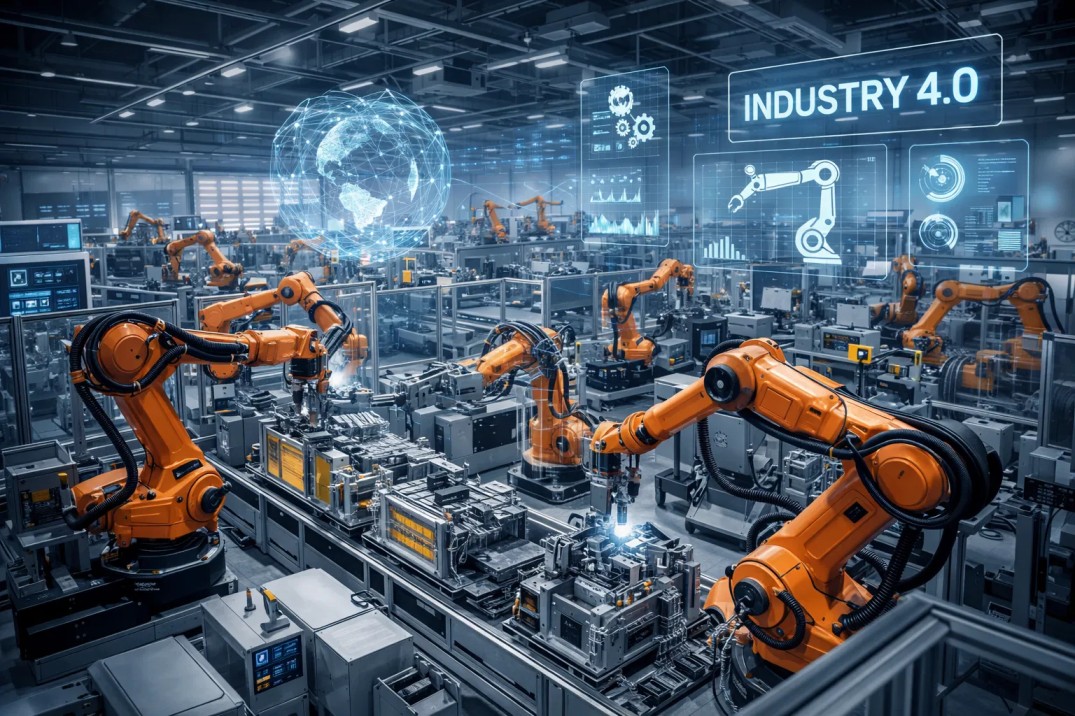

The Zebra 2024 Manufacturing Vision Study revealed 92% of manufacturers have prioritized digital transformation. The study also showed that 61% of manufacturers expect AI to drive growth by 2029, up from 41% in 2024. Plus, according to our Warehouse Vision Study, seven in 10 leaders plan on accelerating timelines of modernization project and automating workflows, and over the next five years, nine in 10 expect to invest in increased supply chain visibility. The adoption of AI-driven strategies and solutions such as machine vision, RFID and AMRs to automate essential business-critical workflows will lead to significant improvements in visibility and data integration across applications, optimizing quality and enhancing frontline performance.

Learn more about how Zebra is helping organizations advance their intelligent automation journey at these sessions:

- The Robotics Executive Roundtable: The Trends & Technologies Driving the Industry, presented by Matthew Wicks: Wednesday, May 14 at 10:30 AM.

- A New Era in Manufacturing: Cloud-based AI Training, presented by Donato Montanari: Wednesday, May 14 at 12:45 PM.

- Multiview Bin Picking and Real-time Robotics – Pushing the Boundaries of 3D Vision-Guided Robotics, presented by Frantisek Takac, Photoneo, now part of Zebra Technologies: Wednesday, May 14 at 1:30 PM.

KEY TAKEAWAYS

- At Automate 2025, Zebra is showcasing new solutions to advance intelligent automation in manufacturing and on warehouse floors to deliver better visibility for processing and quality control.

- Visit Zebra at Booth 3207, on May 12-15 at Detroit’s Huntington Place.

- Talk with representatives of Photoneo, now part of Zebra Technologies, in the Zebra booth and in the Photoneo Booth 641 at Automate.