Controlling all kinematics from a single source, even with your own teach pendant

With the new operating system, all KUKA robot kinematics can be operated with the same system by means of the KR C5 and KR C5 micro controllers for iiQKA.OS2 – from Delta and Scara robots to 6-axis robots of all payload capacities. This will initially apply to small robots, and then to large robots coming later in 2025.

The system can also be used without a KUKA teach pendant with a “use your own device” feature. The KUKA smartPLUG can be docked onto a commercially available tablet and connected with a USB cable. This allows the robots to be programmed and operated intuitively and quickly on the iiQKA.UI.

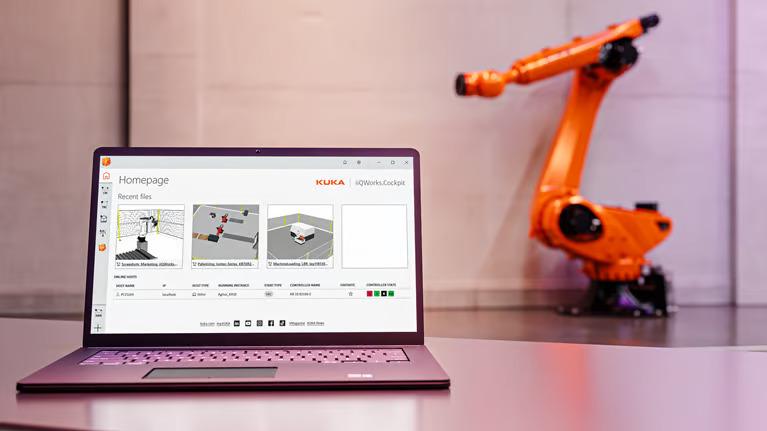

iiQKA.OS2 can detect errors at an early stage thanks to various engineering functions such as simulation, offline programming and comprehensive tests in a virtual environment. This reduces risks and costs considerably.

The optional, powerful expansion board from NVIDIA, available with the KR C5 and KR C5 micro for iiQKA.OS2, enables the integration of AI for vision applications. In addition, the system will be ready for the new ISO 10218:2025, cyber-resilient and IEC 62443-certified – and therefore ideally equipped for future challenges. With iiQKA.OS2, KUKA offers a comprehensive solution for digital manufacturing of the future.