ABB Wins Prestigious Award for Flexley Tug T702 and AMR Studio®, Redefining Smart Factory Automation

Combining Visual SLAM, AI, and intuitive software, ABB's Autonomous Mobile Robot enhances efficiency, safety, and flexibility—streamlining intralogistics and empowering users with no programming expertise.

Image Courtesy: Public Domain

- ABB wins award for first AMR with Visual SLAM & AMR Studio® AI and 3D Vision to efficiently navigate dynamic environments

- Intuitive AMR Studio software requires no programming knowledge, opening access to more users

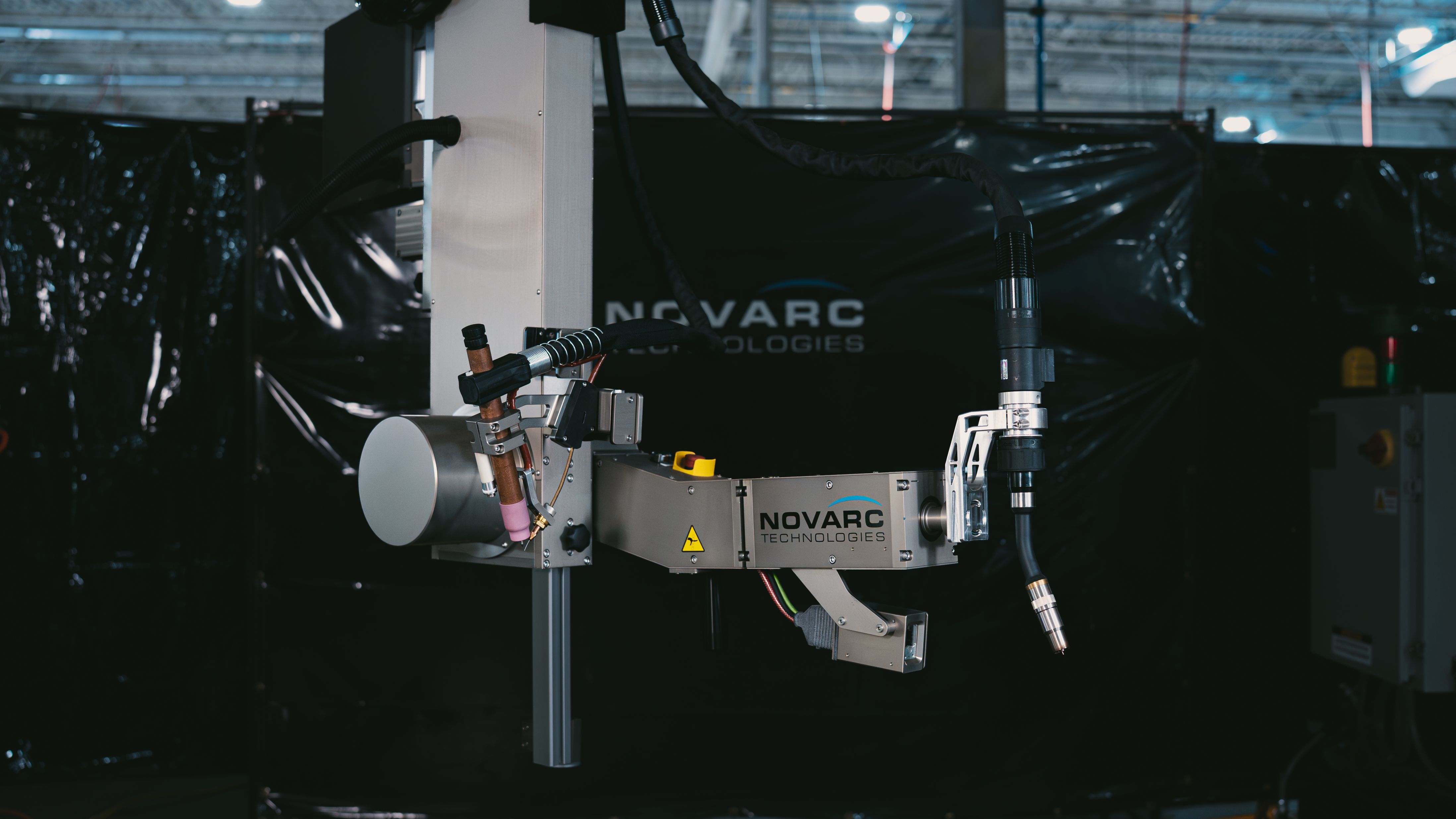

ABB's Autonomous Mobile Robot (AMR) Flexley Tug T702 with Visual SLAM and AMR Studio has won the “Smart Factory: Best Connected Production Line” category in the Advanced Manufacturing Awards. Part of the Advanced Manufacturing Madrid 2024 exhibition, the awards recognize innovations that help companies make their value chains more efficient, sustainable and connected.

“The Flexley Tug T702 with Visual SLAM and AMR Studio combines AI, mobile robots and our intuitive programming software to give our customers new ways to build flexibility and efficiency into their operations,” said Alfonso González, Managing Director AMRs. “Together, they enable companies to benefit from fully autonomous automation of their intralogistics and logistics tasks, enabling them to reduce commissioning time by up to 20 percent, while delivering the safety needed for operations in challenging environments.”

ABB's AMR Studio software revolutionizes AMR fleet management, controlling multiple AMRs through a single system. Users can monitor AMRs in real-time, ensuring smooth and efficient workflows. A major benefit of the software is its simplicity. Designed to be user-friendly, it requires no prior programming knowledge, making it accessible to a broader range of employees, including first time users.

The Visual SLAM navigation technology, powered by AI and 3D vision, significantly enhances the autonomy of AMRs. This advanced technology allows the robots to navigate and map their environment without the need for ground references, resulting in faster, more flexible, and more resilient production processes. Plant workers can focus on higher-level tasks, while the AMRs handle repetitive and labor-intensive duties, boosting overall productivity and efficiency.

Luisa Llompart, Software Portfolio Manager ABB AMRs, accepted the award on behalf of ABB and highlighted the effort that multiple teams of the company have made to continue promoting innovation and accessibility in robotics.

“Winning this award highlights ABB's ongoing commitment to creating the factories of the future, where our autonomous robots can deliver new levels of connectivity, flexibility and efficiency whilst maximizing operator safety and enabling companies to enhance the productivity of their workers,” said Alfonso González.