AI-Powered Robotics Transform Logistics Operations Amid Growing E-commerce Demands

02 October 2024 | Market Trend

As global e-commerce surges, companies are embracing AI-driven robots to streamline warehouse management, optimize inventory, and transform last-mile delivery, setting new standards for efficiency and sustainability in the supply chain.

Picture Courtesy | Robotics Business NEWS

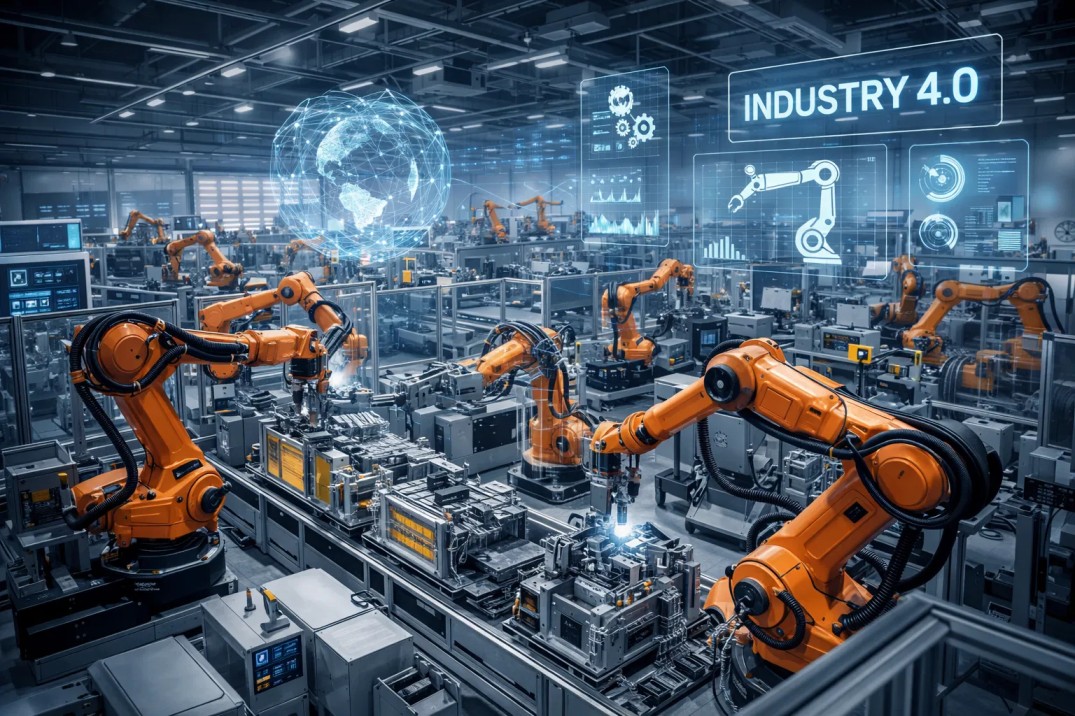

Efficiency and accuracy in logistics are critical. As global e-commerce grows and the demand for faster deliveries intensifies, companies are adopting AI-powered robotics to streamline warehouse operations, optimize inventory management, and enhance last-mile delivery. Autonomous robots, integrated with advanced AI algorithms, are revolutionizing how goods are stored, sorted, and shipped, setting the stage for a more efficient and sustainable supply chain ecosystemInnovations in Autonomous Robotics for Warehouse Operations

Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) are two leading innovations making waves in warehouse management. Unlike traditional static systems, AMRs use AI to navigate dynamic warehouse environments, learning and optimizing routes to transport goods across different sections. These robots can adjust to new information in real-time, avoiding obstacles, reducing downtime, and significantly increasing operational speed.

Companies like Locus Robotics, Fetch Robotics, and GreyOrange are leading the charge in this area. Locus Robotics' LocusBots have shown a productivity increase of over 200% in some warehouses, while Fetch Robotics offers a flexible cloud-based platform for deploying robots without overhauling existing infrastructure. Meanwhile, GreyOrange's Ranger Series integrates AI and machine learning to enhance operational efficiency, allowing the robots to handle inventory and order fulfillment autonomously.

Optimizing Inventory Management with AI and Robotics

Inventory management is another crucial area where AI-powered robots are excelling. The integration of AI in robotics allows for continuous monitoring of inventory levels, ensuring that stockouts and overstock situations are avoided. Ocado, a UK-based online supermarket, has invested heavily in automated systems. Its state-of-the-art Smart Platform uses a combination of AI algorithms and swarm robotics to manage over 50,000 orders per week, with robots zipping through a complex grid system to pick and pack groceries with minimal human intervention.

Amazon Robotics has also become a key player, automating its fulfillment centers with thousands of Kiva robots that move shelving units filled with products to human pickers, reducing picking times by up to 75%. This has allowed Amazon to stay competitive in a market where customers expect rapid delivery options like same-day or two-hour shipping.

Revolutionizing Last-Mile Delivery

Perhaps the most transformative aspect of AI-powered robotics in logistics is its role in last-mile delivery—the final step of the delivery process, which is often the most expensive and inefficient. Companies like Starship Technologies and Nuro are deploying fleets of autonomous delivery robots to address this challenge.

Starship Technologies' robots have already completed over 4 million deliveries in urban areas, operating at a fraction of the cost of human couriers. Nuro, meanwhile, has been testing autonomous delivery vehicles with major partners such as Domino's and Kroger, focusing on grocery and food delivery in suburban areas. Nuro's small electric vehicles navigate residential streets autonomously, offering a sustainable and cost-effective alternative to traditional delivery methods.

Key Players and Their Strategic Pipelines

Several companies are at the forefront of the AI-powered robotics revolution in logistics. Here's a snapshot of some of the key players:

- Amazon Robotics

- Key Innovation: Kiva robots for fulfillment centers

- Growth Strategy: Expanding automation across its global warehouse network

- Recent Developments: Introduction of Pegasus robots, enhancing sortation accuracy by 99%

- Locus Robotics

- Key Innovation: AMRs for flexible warehouse automation

- Growth Strategy: Strategic partnerships with 3PLs (Third-Party Logistics providers)

- Recent Developments: Partnership with DHL Supply Chain to deploy 2,000 AMRs by the end of 2024

- Ocado Group

- Key Innovation: AI-driven automated grocery fulfillment

- Growth Strategy: Licensing its proprietary robotic technology to other retailers worldwide

- Recent Developments: Opening new automated fulfillment centers in North America

- Fetch Robotics

- Key Innovation: Cloud robotics for flexible automation solutions

- Growth Strategy: Focus on interoperability with existing systems

- Recent Developments: Acquired by Zebra Technologies to expand its robotics offerings in retail and logistics

- GreyOrange

- Key Innovation: AI-powered robotic systems for inventory and fulfillment

- Growth Strategy: Expansion into North America and Asia-Pacific markets

- Recent Developments: Partnered with HSBC to finance large-scale robotic deployments across global warehouses

Growth Strategy and Market Projections

The AI-powered robotics market in warehousing and logistics is expected to grow exponentially in the coming years. According to MarketsandMarkets, the global warehouse robotics market is projected to reach $9.1 billion by 2026, with a compound annual growth rate (CAGR) of 11.7% between 2021 and 2026.

The growth is being driven by several factors:

- E-commerce expansion: As online shopping continues to soar, so does the need for automated systems that can handle increasing order volumes quickly and efficiently.

- Labor shortages: With rising labor costs and a shrinking workforce in many parts of the world, companies are turning to automation to fill the gaps.

- Technological advancements: Improvements in AI, machine learning, and sensor technologies are making robots smarter, more reliable, and more adaptable.

What More to Expect?

The future of AI-powered robotics in logistics is not limited to warehouses and delivery services. We are on the cusp of seeing these robots interact more seamlessly with IoT systems, integrating with smart cities and autonomous transport systems. The rise of 5G connectivity will further enhance the real-time capabilities of these robots, making operations faster and more efficient.

Moreover, as sustainability becomes a core focus for industries globally, the role of green robotics—robots that reduce energy consumption and minimize carbon footprints—will be pivotal. Innovations like electric autonomous delivery vehicles and AI-optimized route planning will become standard in the logistics landscape.

AI-Powered Robotics Revolutionizing Manufacturing and Beyond in 2024

As we move through 2024, the integration of AI-powered robotics in industries like manufacturing, healthcare, and construction is reshaping the landscape of automation. From ABB’s Visual SLAM technology enabling autonomous robots to navigate dynamic environments to AI-driven advancements in construction enhancing safety and sustainability, robotics is unlocking new efficiencies across sectors(

The adoption of these technologies not only increases productivity but also helps businesses align with sustainability goals. As AI and robotics continue to evolve, their ability to boost operational performance and foster innovation will solidify their importance across industries, driving continued growth and efficiency improvements into the future